flow from the directional control valve. This

actuator (fig. 10-6) is referred to as an unbalanced

actuating cylinder because there is a difference in

the effective working areas on the two sides of

the piston. Therefore, this type of cylinder is

normally installed so that the blank side of the

piston carries the greater load; that is, the cylinder

carries the greater load during the piston rod

extension stroke.

A four-way directional control valve is

normally used to control the operation of this type

of cylinder. The valve can be positioned to direct

fluid under pressure to either end of the cylinder

and allow the displaced fluid to flow from the

opposite end of the cylinder through the control

valve to the return line in hydraulic systems or

to the atmosphere in pneumatic systems.

There are applications where it is necessary to

move two mechanisms at the same time. In this

case, double-acting piston-type actuating cylinders

of different designs are required. See figures 10-7

and 10-8.

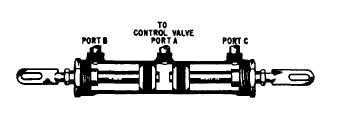

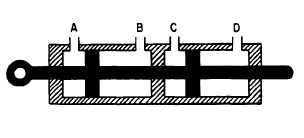

Figure 10-7 shows a three-port, double-acting

piston-type actuating cylinder. This actuator

contains two pistons and piston rod assemblies.

Fluid is directed through port A by a four-way

directional control valve and moves the pistons

outward, thus moving the mechanisms attached

to the pistons’ rods. The fluid on the rod side of

each piston is forced out of the cylinder through

ports B and C, which are connected by a common

line to the directional control valve. The displaced

fluid then flows through the control valve to the

return line or to the atmosphere.

When fluid under pressure is directed into the

cylinder through ports B and C, the two pistons

move inward, also moving the mechanisms

attached to them. Fluid between the two pistons

is free to flow from the cylinder through port A

and through the control valve to the return line

or to the atmosphere.

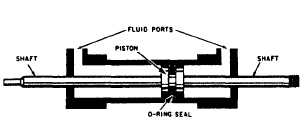

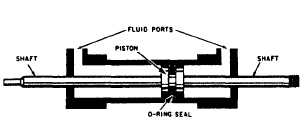

The actuating cylinder shown in figure 10-8

is a double-acting balanced type. The piston rod

extends through the piston and out through both

ends of the cylinder. One or both ends of the

Figure 10-7.—Three-port, double-acting actuating cylinder.

Figure 10-8.-Balanced, double-acting piston-type actuating

cylinder.

piston rod may be attached to a mechanism to

be operated. In either case, the cylinder provides

equal areas on each side of the piston. Therefore,

the same amount of fluid and force is used to

move the piston a certain distance in either

direction.

Tandem Cylinders

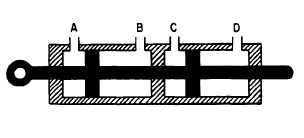

A tandem actuating cylinder consists of two

or more cylinders arranged one behind the other

but designed as a single unit (fig. 10-9). This type

of actuating cylinder is used in applications that

require two or more independent systems; for

example, power-operated flight control systems

in naval aircraft.

The flow of fluid to and from the two

chambers of the tandem actuating cylinder is

provided from two independent hydraulic systems

and is controlled by two sliding spool directional

control valves. In some applications, the control

valves and the actuating cylinder are two separate

units. In some units, the pistons (lands) of the two

sliding spools are machined on one common shaft.

In other applications, the valves and the actuator

are directly connected in one compact unit.

Although the two control valves are hydraulically

independent, they are interconnected mechanically.

In other units, the two sliding spools are connected

through mechanical linkages with a synchronizing

rod. In either case, the movement of the two

sliding spools is synchronized, thus equalizing the

Figure 10-9.—Tandem actuating cylinder.

10-5