2. Remove the sheet. Insert the sheet, flanged

edge down, all the way into the brake. Raise the lower

leaf to make the maximum possible bend.

3. Remove the sheet from the brake. Turn the

sheet so that the side with the 90-degree angle is up, and

slide it into the brake until this angle is flush with the

forward edge of the upper jaw. Raise the lower leaf

through the maximum arc.

4. Raise the upper jaw and slide the sheet farther

into the brake until the edge of the sheet once again is

flush with the front edge of the upper jaw.

5. In the recess that will form the pocket of the

seam, insert a strip of metal of the same gauge as the

metal you are forming. One long strip running the length

of the seam may be used, or several smaller lengths of

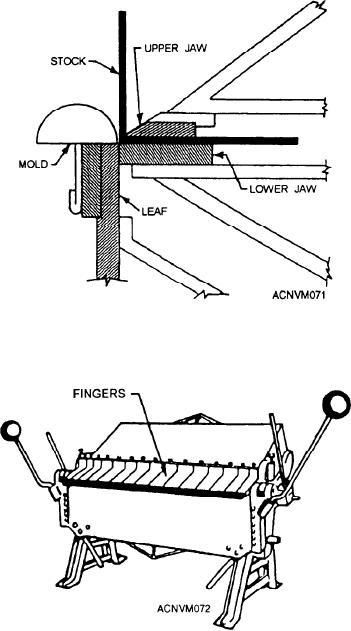

Figure 12-71.--Work ready to be formed over mold on

stripping may be used. The stripping material should be

standard cornice brake.

about 1 inch wide.

6. Close the left-hand clamping device.

7. Use an easy up-and-down motion with the

right-hand clamping device to start pressing the folds of

the seam together. Complete the flattening operation in

the manner described for flattening hems.

8. Turn the sheet over and line up the inner bent

edge with the front edge of the upper jaw. Lower the

upper jaw with the clamping handles.

9. The clamping procedure used in the preceding

step will cause the formed edge of the seam to rise

slightly. To bring this section back in line, work it down

with a wooden mallet.

10. Bend the other portion that fits into the pocket

Figure 12-72.--Box and pan brake (finger brake).

to a 90-degree angle. Be sure the flange is the correct

width.

11. Remove the strips from the pocket.

this will be the right-hand end. After prolonged use on

one end, that end is worn more than the other, thus

12. Insert the flanged edge into the pocket. Tap it

requiring an adjustment.

firmly in place with a mallet. Bend the protruding edge

over with a mallet, and the seam is finished.

The box and pan brake, normally called a finger

brake, shown in figure 12-72, can do everything that the

Some brakes are equipped with molds, others are

cornice brake can do and several things that the cornice

not. You will probably not have much occasion to use

brake cannot do.

molds. However, they are useful for forming special

The upper jaw of the finger brake consists of a series

shapes. The molds are fastened to the brake by means

of steel fingers of varying widths, whereas the cornice

of friction clamps, in such a position that the work can

brake has one long bar. The fingers are secured to the

be formed over them. Figure 12-71 shows sheet that is

upper jaw by thumbscrews, as shown in figure 12-73.

ready to be formed over a mold that is attached to a

brake.

The finger brake is particularly useful in forming

boxes, pans, and other similar shapes. If these shapes

Occasionally one end of a sheet is bent at a sharper

were formed on a cornice brake, you would have to

angle than the other end. The end that made the lower

straighten part of the bend on one side of the box to

quality bend will then need to be adjusted. Normally

12-32