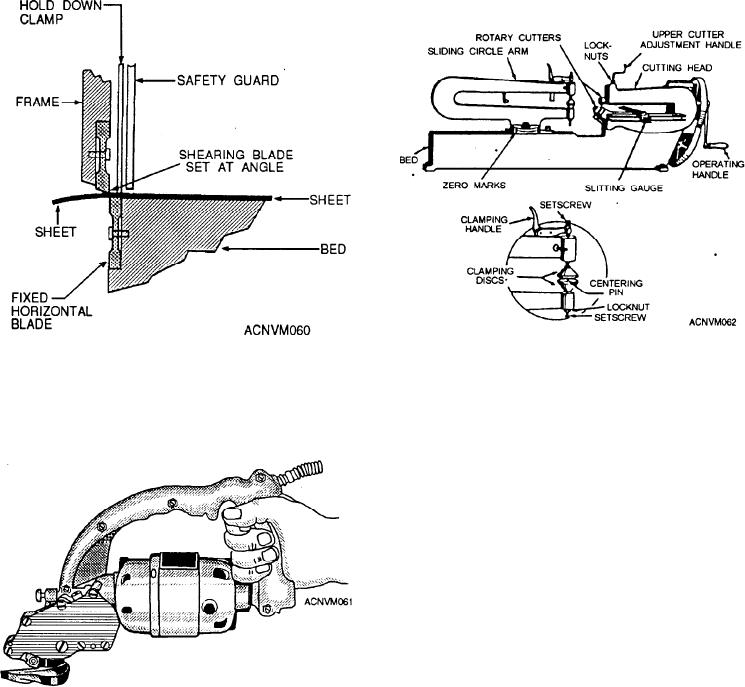

Figure 12-60.--Principle of a shear.

Figure 12-62.--Ring-and-circle shear.

many ships for special types of cutting jobs. When

available, these special shears can simplify your work.

Ring-and-circle shears are used to cut inside and

outside circles. These shears may be hand operated,

such as the one shown in figure 12-62, or they may be

power driven. The following procedure is used to

operate a ring-and-circle shear:

1. Select a piece of stock of the correct size, and

locate the center of the piece. Mark the center with a

prick punch.

2. Adjust the gauge arm of the machine to the

radius of the desired circle.

3. Place the stock in the sliding circle arm. Locate

the center of the stock by working the centering pin of

Figure 12-61.--Portable power-operated shearing tool.

the clamping device into the prick-punch mark.

4. Secure the metal in position by depressing the

a crosshead and at a slight angle to the position of the

clamping handle.

lower blade. The shearing action starts at one end of the

5. Set the locknuts of the upper cutter adjustment

sheet and continues across the sheet in much the same

handle so that the upper cutter, in its lowest position,

way that a pair of scissors cuts paper.

produces a clean cut.

Portable, power-operated shears of the type shown

6. Lower the upper rotary cutter until it comes in

in figure 12-61 are also used to cut sheet metal. They

firm contact with the metal.

can be used to cut curves and notches as well as to make

straight cuts. These tools cut metals of various gauges

7. If the shear is a hand-operated type, turn the

according to the capacity indicated on the nameplate.

operating handle. If it is a power-driven type, push the

starting button. The blank feeds into the shear. Continue

There are special types of shears, some hand

.

operated and some power driven, which are used on

cutting until the disk is cut out completely.

12-27