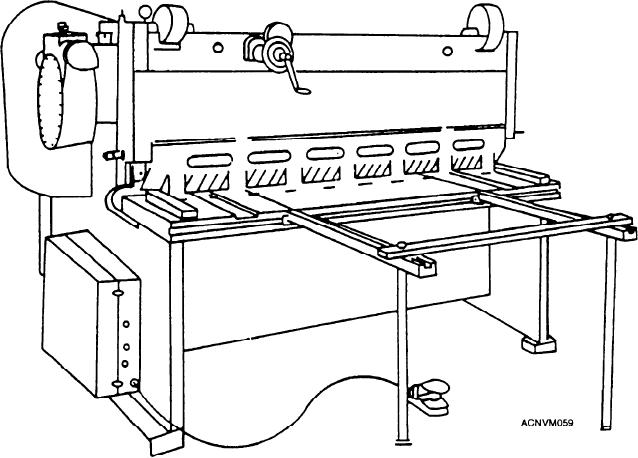

Figure 12-59.--Power-driven squaring shears.

punch a hole in the center of the circle to be cut. Then

Squaring shears are equipped with devices that

serve as stops for sheets when more than one piece of

work your way out to the line of the circle and follow

the same size is required. The stops or gauges are

the line around until the cut is completed.

located on the front, back, and sides of the bed of the

Unless otherwise specified, snips for cutting sheet

shear. They can be adjusted to various lengths and

metal are intended for use on mild steel of relatively

angles.

light gauge. Stainless steel and other special alloy steels

Squaring shears are also equipped with hold-downs

must be cut with special snips or shears that have special

for clamping the sheet in place. The hold-downs used

tool steel inlaid edges.

on powerdriven squaring shears are automatic. After

Some ships have squaring shears installed to use in

the machine has been started and allowed to reach its

making long straight cuts on heavy materials. The type

operating speed, the metal is inserted; a foot treadle is

of squaring shear installed depends on the nature and

then tripped, and the machine automatically clamps the

the amount of work to be done on that ship. Repair ships

sheet into position and makes the cut. Hand operated

have large power-driven squaring shears such as the one

hold-downs are usually used on treadle-operated

shown in figure 12-59.

squaring shears. The sheet to be cut is inserted, the

hold-down handle is adjusted, and the cut is then made

Squaring shears are designed for various capacities,

by depressing the foot treadle. After the cut has been

which must never be exceeded. Nameplates indicating

made, the hold-downs are released and the sheet can

the maximum thickness of material to be cut are

then be removed from the machine.

installed on each machine by the manufacturer. In

general, the thickness specified by the manufacturer is

The principle of the shear is shown in figure 12-60.

for low-carbon or mild steel. If alloy steel must be cut,

The lower blade of the shear is stationary and is attached

the thickness of the alloy steel also must not exceed that

in a parallel position to the bed of the machine. The

upper blade, which is the movable blade, is attached to

specified by the manufacturer.

12-26