lines and your second triangle is completed. Continue

this process until you reach line 7-14. At this point, you

will have completed one-half of the pattern

development. The other half is identical, so you will not

have to lay out the other half.

TRANSFERRING THE PATTERNS TO

METAL

Many of your patterns will be laid out right on the

metal. However, there will be times when you will have

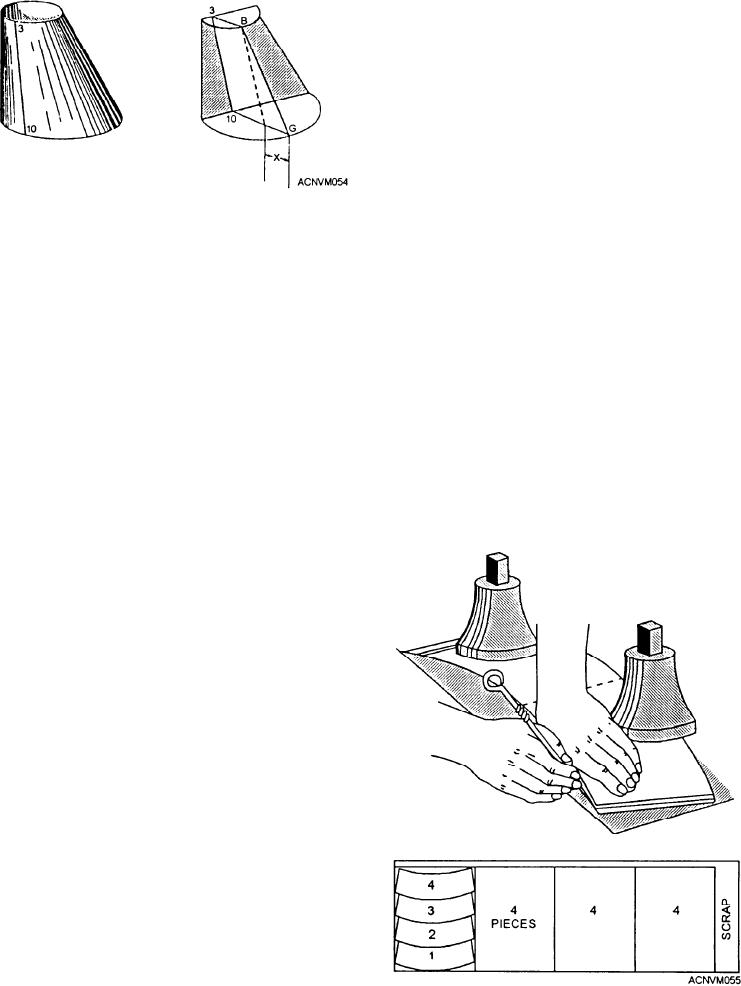

Figure 12-54.--Determining true length of a line.

to make the development on paper. Then, you must

transfer the pattern to the metal that you plan to work.

When you transfer these measurements, you must avoid

Figure 12-54 shows why the difference between the

mistakes or your piece will not come out as required.

lengths of line B-3 and line G-10 must be used as the

Occasionally, you may cut out the pattern from

length of the bottom leg of the triangle to get the true

template paper. Hold the pattern firmly in place and

length of line 3-10.

trace around the edges, as shown in figure 12-55. The

If the half-plans of the front view (fig. 12-53) were

break lines (where you bend the work) are located by

bent forward 90 degrees and the entire front view

using a prick or center punch and marking through the

revolved about 30 degrees to the right, the view would

pattern on to the metal.

appear as shown in figure 12-54.

If you were in a large production shop where you

A perpendicular dropped from the top half-plan

made the same piece over and over again, you would

edge at B will be parallel to line 3-10 and intersect line

make a metal pattern and use it to trace around and

G-10 as indicated. That intersection represents the

locate break lines and holes. Normally, your work is so

proximity of the top edge to the bottom edge (top view,

varied that you will develop the stretchout when you

fig. 12-53). The distance between the point of

need it. The future use of metal patterns is limited.

intersection and point G (represented in the pictorial

view by X shown in fig. 12-54) determines the length

of the base leg required to plot the true length of line

3-10. Each line in the front view (fig. 12-53) is plotted,

and the true length is obtained in the same manner.

With the true length of all the solid and broken lines

established, lay out the development. First, draw a

straight line that is almost vertical. Towards the top of

the line, mark a point and label it point 1. Set your

dividers for the length of line 1-8 in the front view of

figure 12-53. Working from point 1 in the development,

scribe an arc to locate point 8 as shown in figure 12-53.

Using line 1-8 as a base line, you can now lay out the

rest of the development. The first triangle to be laid out

is 1-8-2. To obtain point 2 in triangle 1-8-2, use one

equal spacing from the top half-circle of the front view.

Using point 1 as a pivot point, scribe an arc. Then, using

the true length of line 2-8, and using point 8 as the pivot

point, scribe an arc across the first arc to locate point 2.

Draw in your lines and you will have completed triangle

1-8-2. The next triangle to be developed is 8-2-9. To

locate point 9, use one equal space of the lower

half-circle from the front view of figure 12-53. Scribe

an arc from point 8. Then, using the true length of line

2-9, strike an arc using point 2 as your pivot point. Point

9 is located where the two arcs intersect. Draw in your

Figure 12-55.--Transfering patterns to metal.

12-24