The steps used to make a ring by this method are as

follows:

1. Scribe the inner and outer concentric circles

using the desired radii.

2. Make a series of straight cuts on the slitting

shears as close to the outer circumference as possible.

3. File or grind the outer circumference down to

the scribed line.

4. Drill, punch, or chisel the inner material from

the disk. Take care not to work too close to the inner

scribed line.

A throatless shear is a heavy-duty machine that can

take material up to l/4 inch in thickness. Smaller

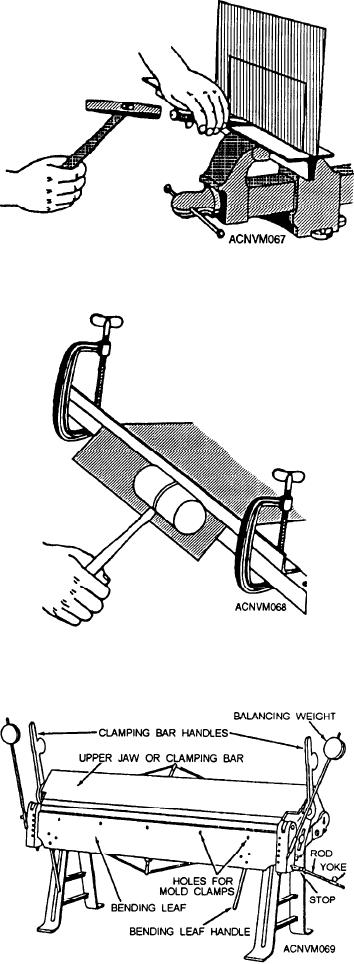

Figure 12-67.--Cutting light sheet metal with a cold chisel.

power-driven and hand-operated models are available.

The throatless shear is normally used to cut out shapes

that have an irregular curved edge. There are no guides

on this type of machine. You control the cut by changing

the direction of the sheet so that the blades cut along the

lines scribed on the material.

There is a wide varity of equipment for cutting sheet

metal. However, you may be assigned to a ship that does

not have the equipment nor the room to keep it. In this

case, you will have to depend on your normal shop tools.

You can do a number of simple cutting operations on

light sheet metal while the material is held firmly in a

bench vise. Figure 12-67 shows the method used to cut

sheet metal, held firmly in a vise, by using a chisel and

hammer. Also you may use a hacksaw to make some of

the cuts on the sheet metal held in a vise.

FORMING SHEET METAL

Sheet metal may be formed either by hand or with

Figure 12-68.--Hand forming a bend in sheet metal.

the aid of various special tools and machines. The hand

forming of a bend is shown in figure 12-68.

The sheet is laid on a workbench or other flat

surface, with the required amount projecting over the

edge. A piece of angle iron is laid on top of the sheet

with its edge even with the edge of the workbench.

C-clamps are used to hold the angle iron and the sheet

in place. Form the bend first by bending the entire length

of the sheet with your hands. Then finish the bend by

striking the bend area with a wooden mallet.

Sheet Metal Brakes

Sheet metal brakes produce more uniform bends

than those made by hand. They also require

considerably less effort. A standard cornice brake is

shown in figure 12-69. Before you use this machine,

Figure 12-69.--Standard cornice brake.

two adjustments must be made.

12-29