Figure 12-85.--Grooved scam locked with prick-punch

7. Secure the seam in position by making

prick-punch indentations about l/2 inch in from each

end of the seam, as shown in figure 12-85.

Specialized Metal Forming Machines

Large shops have rotary machines for burring,

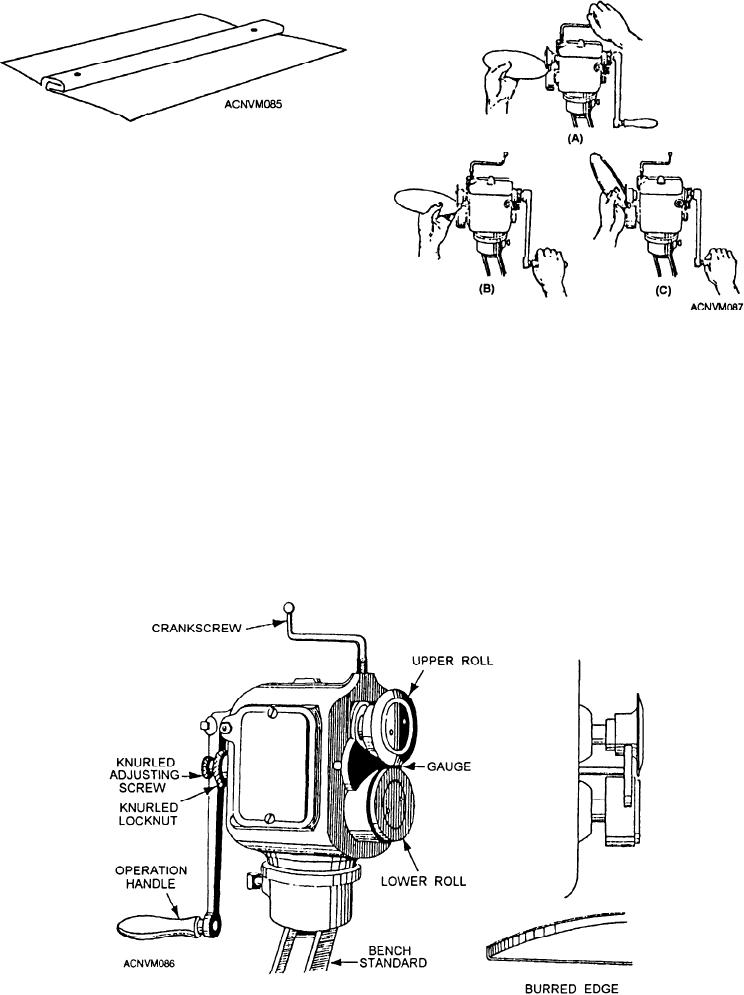

Figure 12-87.--Burring a disk.

turning, wiring, beading, setting down, grooving, and

crimping sheet metal. Some machines are of the

combination type, having one head with several sets of

Figure 12-87 shows the use of the burring rolls. The

rolls. A combination rotary head with burring rolls

steps in burring a disk are as follows:

mounted is shown in figure 12-86. Sets of rolls for

1. Adjust and align the rolls so that the inside edge

burring, turning, wiring, and elbow edging can be

of the top roll fits over the shoulder of the bottom roll.

installed on this rotary head.

Make the clearance equal to the thickness of the metal.

The burring rolls are used to turn an edge at right

(Insufficient clearance will cause the top roll to act as a

angles to form burrs or narrow flanges for seams and

shear and damage the stock.)

hems. A typical use of the burring rolls is for burring

2. Set the gauge to turn up the desired amount of

the disks that form the bottoms of some tanks and

metal. This is usually from l/8 inch to 3/16 inch.

buckets.

Figure 12-86.--Combination rotary machine (shown with burring rolls).

12-37