should be enough to form the head on the rivet. A

figure 12-101. These are high-strength, precision-made,

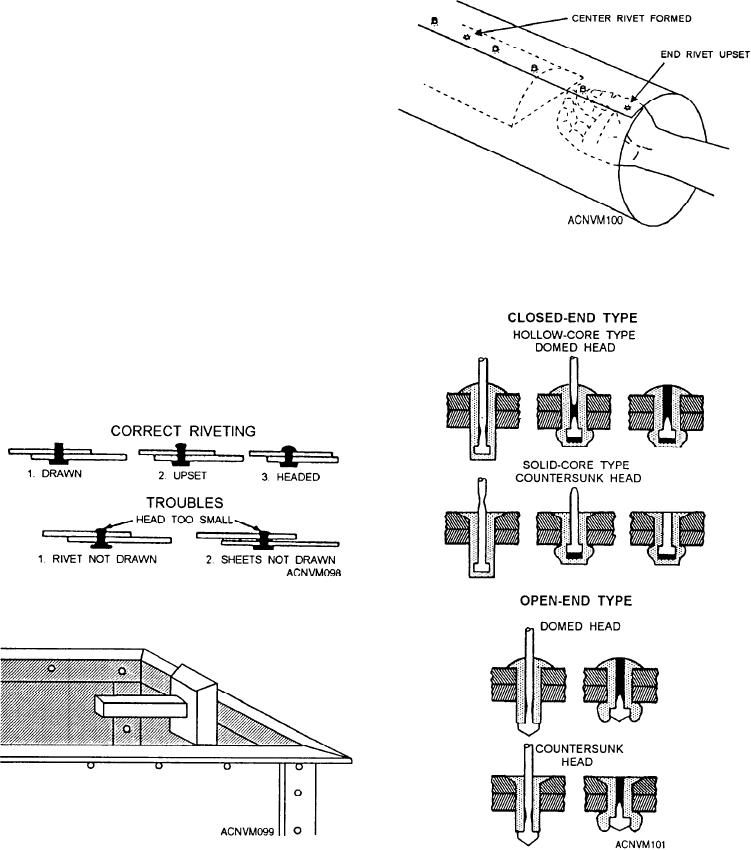

correctly drawn, upset, and headed rivet is shown in the

hollow rivets assembled on a solid mandrel which forms

top part of figure 12-98. The lower part of this

an integral part of the rivet. They are especially useful

illustration shows the results of incorrect riveting

for blind fastening, where there is either limited or no

procedures.

access to the reverse side of the work.

To rivet a seam when you cannot use a stake or a

bench top to back up the rivet, use a hand dolly like the

one in figure 12-99.

To rivet a seam of a cylinder, such as the one shown

in figure 12-100, use a hollow mandrel stake or some

other suitable bar as backing for the rivets. The

procedure for riveting a seam in a cylinder is as follows:

1. Place rivets in the end holes, and slip the piece

over the stake or bar.

2. Draw the seams together and upset the end rivets

enough to hold the structure together.

3. Insert the center rivet. Draw, upset, and head this

rivet.

Figure 12-100.--Riveting a seam in a cylindrical section.

4. Complete the seam by riveting from the center

to one end and then from the center to the other end.

Complete the drawing, upsetting, and heading of each

rivet before you move on to the next rivet.

Besides the sheet metal rivets already discussed,

you will also use the pop rivets like those shown in

Figure 12-98.--Correct and Incorrect riveting.

Figure 12-99.--Hand dolly used to back up rivets.

Figure 12-101.--Pop rivets.

12-41