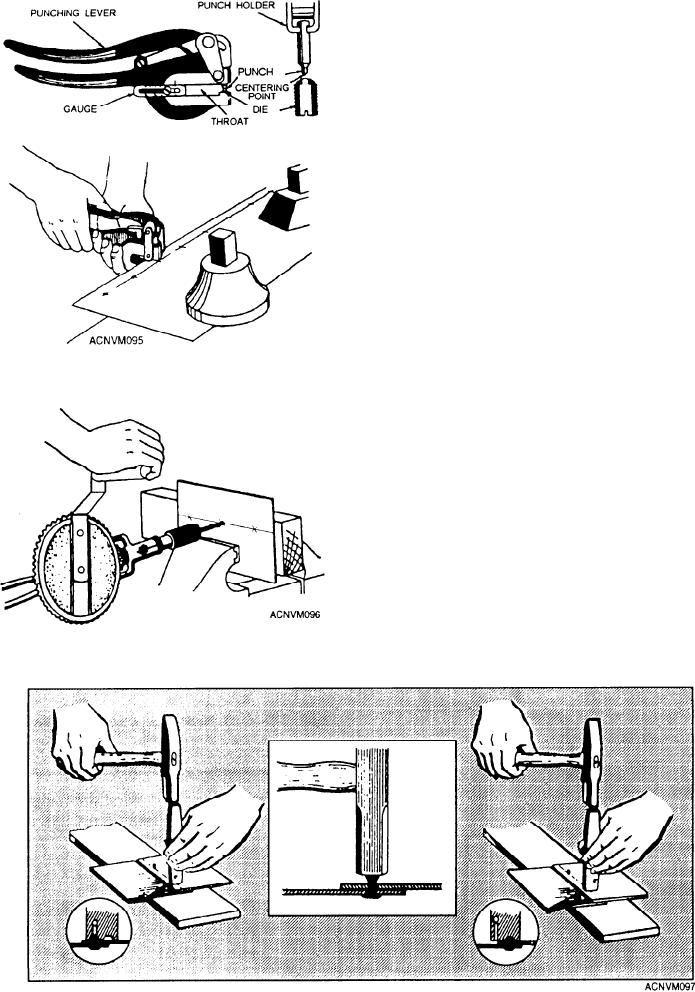

If the holes are located near the edge of the sheet, a hand

punch, similar to the one shown in figure 12-95, can be

used to punch the holes. If the holes are farther away

from the edge, you can use a deep-throated punch

(either hand operated or power driven) or you can drill

the holes. A breast drill used to drill holes for rivets is

shown in figure 12-96. Drill the hole slightly larger than

the diameter of the rivet to provide a slight clearance.

Riveting involves three operations: drawing,

upsetting, and heading. These are illustrated in figure

12-97. A rivet set and a riveting hammer are used to

perform these operations. The procedure for riveting

sheet metal is as follows:

1. Select a rivet set that has a hole slightly larger

than the diameter of the rivet.

2. Insert the rivets in the holes. Rest the sheets to

be joined on a stake or on a solid bench top, with the

rivet heads against the stake or bench top.

Figure 12-95.--A hand punch.

3. Draw the sheets together by placing the deep

hole of the rivet set over the rivet and striking the head

of the set with a riveting hammer. Use a light hammer

for small rivets and a heavier hammer for larger rivets.

4. When the sheets have been properly drawn

together, remove the rivet set. Strike the end of the rivet

LIGHTLY with the riveting hammer. The process of

spreading the end of the rivet to expand it so that it will

hold the sheets together is known as upsetting the rivet.

Do not strike the rivet too hard or else you might distort

the metal around the rivet hole.

5. Place the heading die (dished part) of the rivet

set over the upset end of the rivet and form the head.

Figure 12-96.--Drilling holes with a breast drill.

One or two hammer blows on the head of the rivet set

Figure 12-97.--Drawing, upsetting, and heading a rivet.

12-40