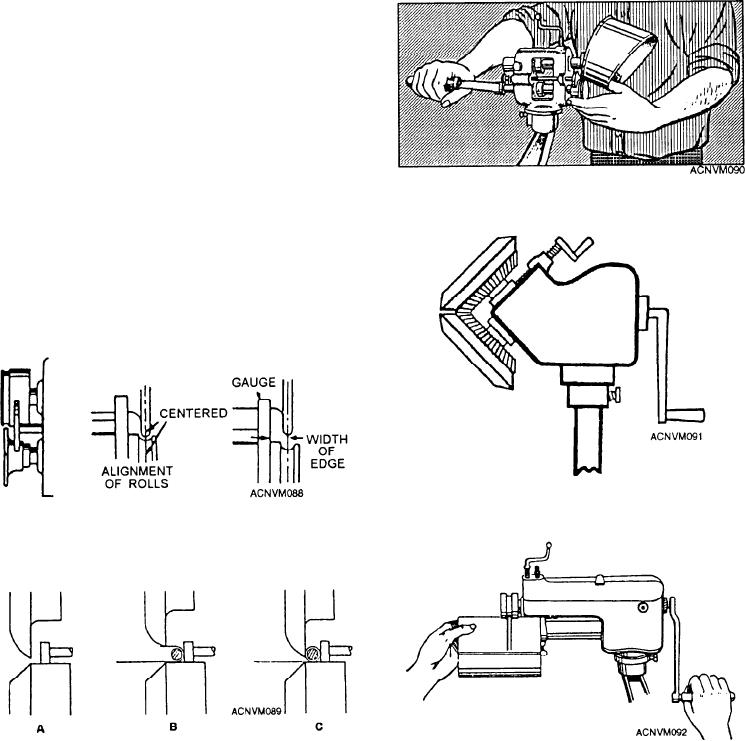

Elbow edging rolls are similar to turning rolls

3. Place the disk in position, as shown in figure

except that the elbow rolls have V-grooves in the lower

12-87, and move the top roll down until it grips the stock

rolls. Figure 12-90 shows a piece of an elbow being

and creases it slightly.

edged. One edge is turned in while the other is turned

4. Crank the handle. Keep the edge of the disk tight

out. The pieces of the elbow are assembled and held

against the gauge. Allow the disk to revolve as you turn

together by interlocking the edges.

the handle.

The setting-down machine, shown in figure 12-91,

is used to close single seams. The beveled jaws grip the

The first revolution should be made slowly so that

seam and mash it down tightly and smoothly.

you can get the burr established accurately. After you

Another specialized machine that you may have in

have made the first revolution, you can crank faster.

your shop is the deep-throated beading machine (fig.

Raise the disk slightly after each revolution.

12-92). Several types of beading rolls may be used with

Turning rolls (fig. 12-88) are used on the

combination rotary machine for forming rounded

flanges that are similar to burred edges except that they

have radii. Several sets of turning rolls are usually

provided. To use the turning rolls, be sure the rolls are

properly aligned and the gauge is properly set. Then

hold the edge of the metal firmly against the gauge

during the first revolution.

Special wiring rolls are used to shape the metal

around a wire. The edge of the metal is first turned on

a brake or on the rotary turning rolls. The wiring rolls

(fig. 12-89) are then used to complete the job. Wiring

Figure 12-90.--Elbow edging rolls for combination rotary

rolls may be used on either straight or curved edges. In

machine.

making a wired edge, be sure to allow enough metal so

that the wire will be completely covered; in general, the

allowance for a wired edge is 1 l/2 times the diameter

of the wire for thin metals, and slightly more than this

for thicker metals.

Figure 12-91.--Setting down machine.

Figure 12-88.--Turning rolls for combination rotary machine.

Figure 12-92.--Deep-throated beading machine.

Figure 12-89.--Wiring rolls for combination rotary machine.

12-38