Now lay out the rivet holes for the seam and for

SHEET METAL PRACTICE PROJECTS

fastening the shelf to the body of the locker. Then lay

As soon as you have learned the basic operations of

out the locker's back and shelf. Mark the locations of

laying out, cutting, forming, and joining sheet metal,

the rivet holes to match those on the main body of the

you will be ready to try your hand at fabricating various

locker. Be sure to provide for a stiffening flange on the

objects. You should have no trouble in laying out and

front of the shelf when you lay out the shelf.

fabricating boxes, pans, cylinders, funnels, ells, tees,

The next step is to lay out the door. Remember, all

elbows, and many other sheet metal items, if you follow

the layout lines will be on the inside of the sheet when

the procedures that were given in this chapter. It takes

it is folded up, so the actual door will be slightly larger

a lot of practice to develop a skill for sheet metal work.

than the layout. Make allowances for this so that the

All your practicing should be done on scrap metal until

door will fit into the jamb. Also, the door must not make

you are good enough to turn out finished articles

a tight fit. It must have clearance so that it can open and

without wasting material.

close freely. Generally, twice the thickness of the metal

Building a locker is a good practice project because

is allowed for this clearance.

it involves so many aspects of sheet metal layout and

After all the pieces have been laid out, trimmed,

fabrication. The locker described here is fairly simple.

notched, and the rivet holes made, the next step is to

You will have to develop your own plans for a more

form the locker to its shape. It does not matter which

elaborate or an odd-shaped locker.

part of the locker you form first. The back has four

The first thing to consider in building a locker is the

90-degree bends that will form the flanges of the

outside dimensions. Then decide on the thickness of

Pittsburgh lock seam. Form the hem first on the shelf,

metal you will use, the method of seaming, the number

then the stiffening flange. The tabs for riveting the shelf

and location of shelves, and the type of door it will have.

to the main body of the locker may be bent either up or

Plan out all of these details before you start your layout.

down.

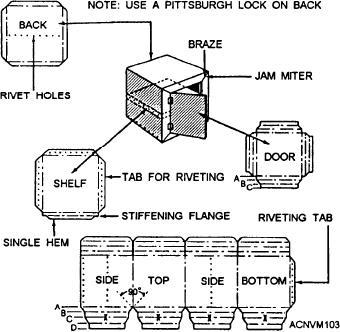

Figure 12-103 shows a locker that has one riveted

Form the pocket for the Pittsburgh lock seam on the

shelf. The locker is assembled by using Pittsburgh lock

main body of the locker. Then form the jamb on the

seams and rivets. The door is flush to the front side and

opposite edge of the sheet. Follow these procedures for

is swung on exposed hinges. A hasp and staple are used

bending the jamb:

as a securing device.

Lay out the main body of the locker. Provide

1. Transfer the lines of the jamb (indicated by X in

sufficient allowances for all of the scams and the

fig. 12-103) to the reverse side of the sheet.

doorjamb. One Pittsburgh lock seam is used for the

main body of the locker, and another one is used for the

back. The layout for the doorjamb is determined by the

following factors:

1. The size of the door in its relation to the size of

the locker. (The difference between the size of the door

and the size of the locker controls dimension A in fig.

12-103.)

2. The thickness of the door. (This controls

dimension B in fig. 12-103.)

3. The width of the stop (C in fig. 12-103).

Normally the stop is about 3/8 inch to l/2 inch in width.

4. The allowance for the single hem (D in fig.

12-103). This allowance will be slightly less than that

of the stop.

The next step is to lay out the notches. Square

notches are used for the Pittsburgh lock scam. A

combination of notches is required for the doorjamb. A

is laid out at 45, B at 90, C at 45, and D at 90 to the

Figure 12-103.--Fabricating a locker.

base line.

12-43