is impractical or the access hole is required to be larger,

the cut. The final step is to cut the access hole using a

follow the steps required for new access holes. If you

cutting torch or other method.

must make the access cut larger or where more than two

REINSTALLATION OF THE PATCH.--After

multiple cuts and replacements have been made,

the equipment has been removed and new equipment

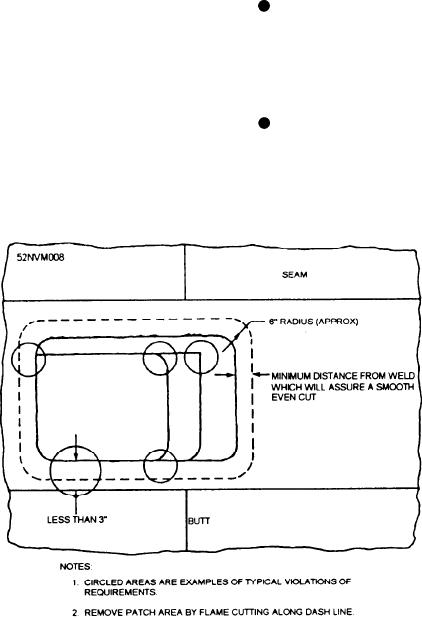

remove and replace the patch. Figure 13-54 shows

has been reinstalled, you will be required to reinstall the

patch removal involving more than two existing cuts

patch. If the removed plate is still usable, it should be

and some of the typical mistakes made while making

reinstalled. If the plate cannot be reused, cut a new

access cuts.

closure plate using the old plate as a guide. Determine

the weld joint design to be used and bevel the patch and

INSTALLING WATERTIGHT DOORS,

the bulkhead or hull to the required angle. Install the

HATCHES, AND SCUTTLES

patch in place and check clearance as required by the

weld joint design from MIL-STD-22.

As a shipfitter, you will replace numerous watertight

fixtures in your career. This is a relatively easy process

WELDING IN CLOSURE PATCHES.--

that involves no special skills. However, fixtures can be

Welding of closure patches should be done by certified

installed incorrectly if special precautions are not

welders and inspected by NDT personnel. Welding is

followed. When installing watertight closures, you

usually done using the block welding sequences to

should keep the following suggestions in mind:

reduce weld metal cracking. You would usually weld

the straight edges of the plate first and comers last to

allow the comers to expand and reduce stress. If you

Ensure the watertight door has been properly

are using a butt joint design, you must backgouge the

maintained before cutting out the door. Some

root to remove impurities introduced during the

major problems with watertight fixtures are

welding process. This is usually accomplished after the

simply a lack of PMS and fixtures may not need

first side is completely welded or enough weld metal

to be replaced.

has been deposited to allow for backgouging.

Check the door and frame for warping.

Cutting Access Holes Involving Previously

Sometimes the door is warped but the

Made Joints

frame is straight. If the door is warped,

replace the door. If the frame is warped, it

When cutting access holes involving previously

must be cut out and replaced.

made cuts, cut in the center of the existing weld. If this

Figure 13-54.--Patch removal involving more than two existing multiple cuts.

13-48