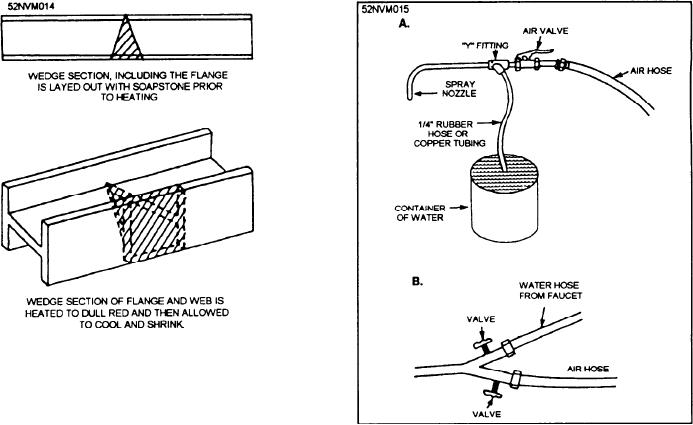

Figure 13-60.--Developing a curve without locked-in stresses.

and no danger of snapping the curve out later by

accidental overload.

Figure 13-61.--Water spray torch used for reducing cooling

time.

Water Spray Equipment

The water spray torch shown in figure 13-61 may

--Select the correct material for the job. Selecting

be used to reduce cooling time. The torch consists of a

materials for the fabricating plate structures is

nozzle, a "Y" fitting, a control valve, and a l/4-inch

essentially a design problem, requiring a thorough

rubber hose. The air hose is connected to the ship's

knowledge of the properties of materials. The materials

service compressed air and the rubber hose is run to a

for most shipboard fabrication jobs are specified in the

pail of water. When you open the control valve, the rush

job order or on the blueprints. You must ALWAYS

of air past the orifice in the "Y" fitting draws some

consult these sources of information before the material

water into the air stream, creating an atomized spray.

is selected. However, you should know enough about

When the spray strikes the hot plate, it turns into steam

the properties of materials to be able to make an

and absorbs a substantial amount of heat. One pound

intelligent selection when this responsibility is left up

of water will absorb 142 Btu while vaporizing into

to you.

steam. Because of the heat requirements for

--In making a repair or replacement, substitution

vaporization, the cooling is rapid, even with the use of

of one material for another requires a knowledge of the

only a small amount of water. Since all of the sprayed

service conditions that the piece must withstand.

water is vaporized, the work will remain dry.

Low-carbon steel has an ultimate tensile strength of

60,000 psi and cast iron has an ultimate tensile strength

FABRICATION EXAMPLES

of 20,000 psi. When you substitute low-carbon steel for

cast iron, the cross-sectional area of the steel need

The variety of fabrication problems that arises on

only be one-third that of the cast iron if tensile

board ship is almost endless. The examples in this

strength is the ONLY consideration. In many cases,

chapter are not to be considered as a complete listing of

rigidity will be the controlling factor. When it is

jobs you may have to perform.

necessary to maintain the same rigidity, a low-carbon

steel piece would have to be four-fifths the thickness

The following basic considerations apply to most

fabrication jobs:

of the cast-iron piece. When substituting another

13-52