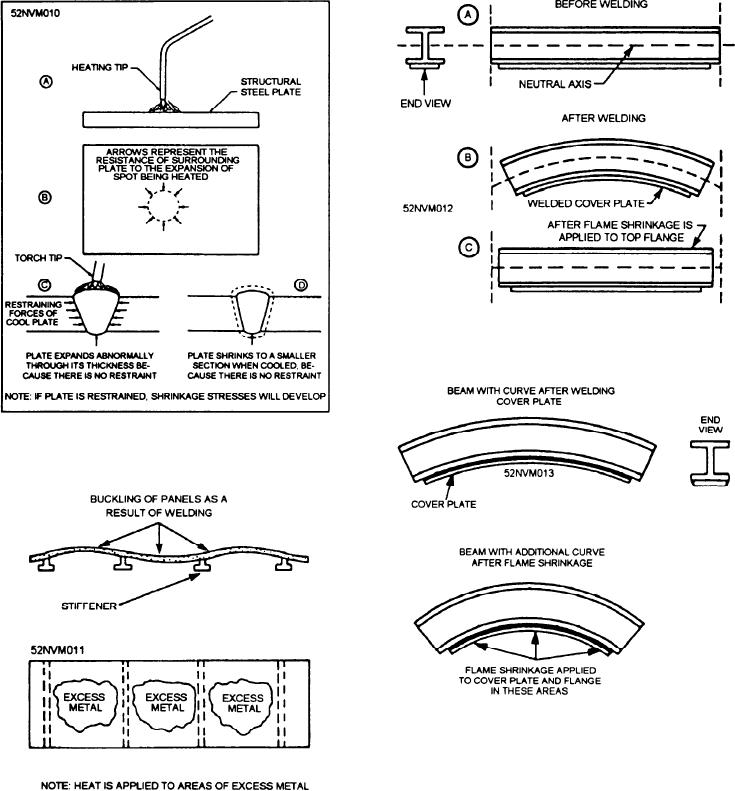

Figure 13-58.--Flame shrinkage used to straighten beam with

a welded cover plate.

Figure 13-56.--Flame shrinkage used to correct distortion.

Figure 13-59.--Developing a curve in a beam.

straight at the start. A wedge-shaped area is marked off

on the web and lower flange with soapstone. The

Figure 13-57.--Flame shrinkage used to control distortion of

wedged area is then heated to a dull red, using one or

panels with welded stiffeners.

more torches. When the wedged area is a dull red,

remove the heat and allow the area to cool. The

resist the load and maintain the curvature. You can

curvature produced should then be noted. Then mark

accomplish this by flame shrinking the beam flange

off other areas and repeat the process until you get the

along with the cover plate.

desired curvature.

Figure 13-60 illustrates the technique of using

This type of flame shrinkage produces the same

flame shrinkage to develop curves in a beam or girder

results as if the entire beam had been heated red hot and

(with or without a cover plate) in such a way that little

or no locked-in stress is developed. The rolled beam is

bent to shape. There will be little or no locked-in stress

13-51