soldering it. Heat the spot by holding the bit

against the work. The metal to be soldered

must absorb enough heat from the bit to melt

the solder, or the solder will not adhere.

8. After the pieces have been firmly fastened

together, solder the seam. Hold the bit so that

one tapered side of the head is flat against the

seam, as shown in figure 9-27. When the solder

begins to flow freely into the seam, draw the

bit along the seam with a slow, steady motion.

Add as much solder as necessary, without

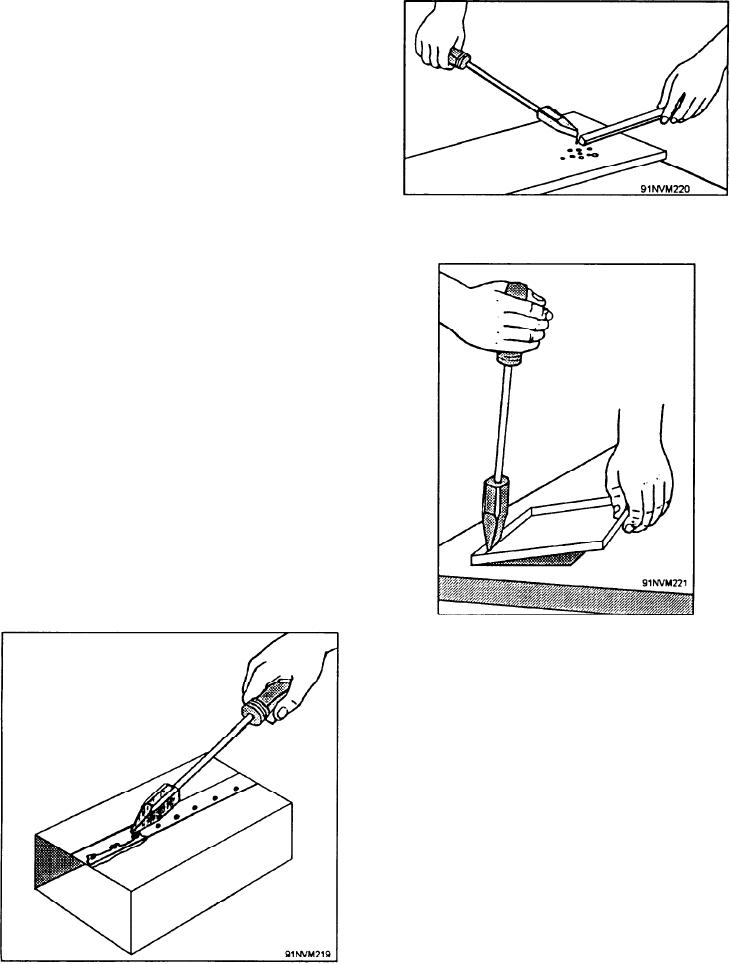

Figure 9-30.--Making solder beads.

raising the bit from the work.

9. To make the best soldered seams, solder

without lifting the bit from the work and

without tracing completed work.

10. Allow the joint to cool and the solder to set

before moving the joint.

11. If you used a corrosive flux, clean the joint by

rinsing it with water and then brushing or

wiping it with a clean, damp cloth.

Riveted seams are often soldered to make them

watertight. Figure 9-29 shows the procedure for

soldering a riveted seam.

Sometimes solder beads or solder shots are used to

solder square, rectangular, or cylindrical bottoms. To

make the solder beads, hold solder against a hot bit and

allow the beads to drop onto a clean surface, as shown

in figure 9-30.

Figure 9-31.--Soldering a bottom seam.

To solder the bottom seam with solder beads, first

flux the seam. Then drop one of the cold beads of solder

in the bottom of the container. Heat, clean, and dip the

soldering bit and place it against the seam, as shown in

figure 9-31. Hold the soldering bit in one position until

the solder starts to flow freely into the seam. Draw the

bit slowly along the seam, turning the work as you go.

Add more beads as you need them. Reheat the copper

as necessary.

Be very careful not to overheat an electric soldering

bit. Never go off and leave an electric soldering iron

plugged in. Overheating will probably bum out the

electrical element and damage the tinning.

TORCH SOLDERING

Parts to be joined may be too large to be heated by

Figure 9-29.--Soldering a riveted seam.

a soldering bit, or shaped in a way that would make rapid

9-28