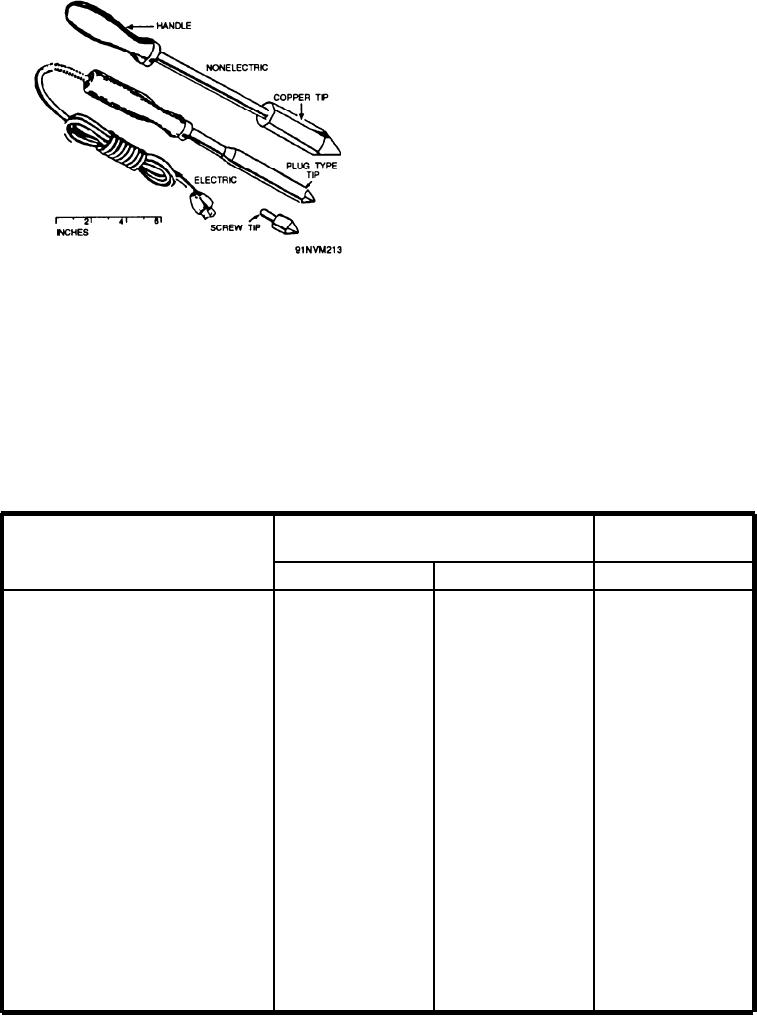

The electric soldering iron (fig. 9-23) transmits heat

to the copper bit after the heat is produced by an electric

current that flows through a self-contained coil of

resistance wire; this coil is called the heating element.

Electric soldering irons are rated according to the

number of watts they consume when operated at the

voltage stamped on the iron, and the diameter of the

copper bit in inches (table 9-7).

There are two types of bits on electric irons. They

are plug bits that slip into the heater head and that are

held in place by a setscrew, and screw bits that are

threaded and that screw into or onto the heater head.

Some bits are offset and have a 90-degree angle for

Figure 9-23.--Soldering irons

soldering joints that are difficult to reach.

Electric iron bits must be securely fastened in the

A nonelectric soldering iron (fig. 9-23) is sized

heater unit. The bits must be clean and free of copper

according to its weight. The commonly used sizes are

oxide. Sometimes the shaft oxidizes and causes the bit

the 1/4-, 1/2-, 3/4-, 1-, 1 1/2-, 2-, and 2 1/2-pound irons.

to stick in place. Remove the bit occasionally and scrape

The 3-, 4, and 5-pound sizes are not used in ordinary

off the scale. If the shaft is clean, the bit will receive

work Nonelectric irons must be heated over a gas

more heat from the heater element, and it will be easier

to remove when you need to replace the bit.

flame.

Table 9-7.--Selection of Soldering Iron for Work to be Done by Copper Bit Size

Externally

Electrically

Heated Irons

Heated Irons

Work to be done

Choice of Bit Dia.

Heat Rating Watts

Size of Bit, lb.

1/4 to 7/16

44-52

1/2

Very light soldering.

3/8 to 1/2

60-70

1

Medium soldering of electrical

appliances and light manufacturing.

1-1/2

3/8 to 9/16

85-100

Fast soldering on radios, electrical

appliances, and light medium

manufacturing.

Medium light soldering on tin ware,

5/8 to 7/8

130-150

2

plumbing, and wiring.

High-speed soldering of light tin

5/8 to 1

170-200

2-1/2

ware and small metal patterns.

Medium manufacturing such as

7/8 to 1-318

225-250

3

ventilation ducts and other shipboard

repairs.

Heavy tin ware, metal patterns,

1-1/8 to 1-3/8

300-350

4

galvanized iron and copper.

Heavy ventilation ducts, tanks,

1-3/8 to 1-7/8

350-650

5

plumbing, and ship building.

9-24