Filing and Tinning Copper Bits

New copper bits must be tinned (coated with solder)

before they are used. Also, bits must be filed and

retinned whenever they have been overheated or have

lost their coating of solder. The procedure for filing and

tinning a bit is as follows:

1. Heat the bit to a cherry red.

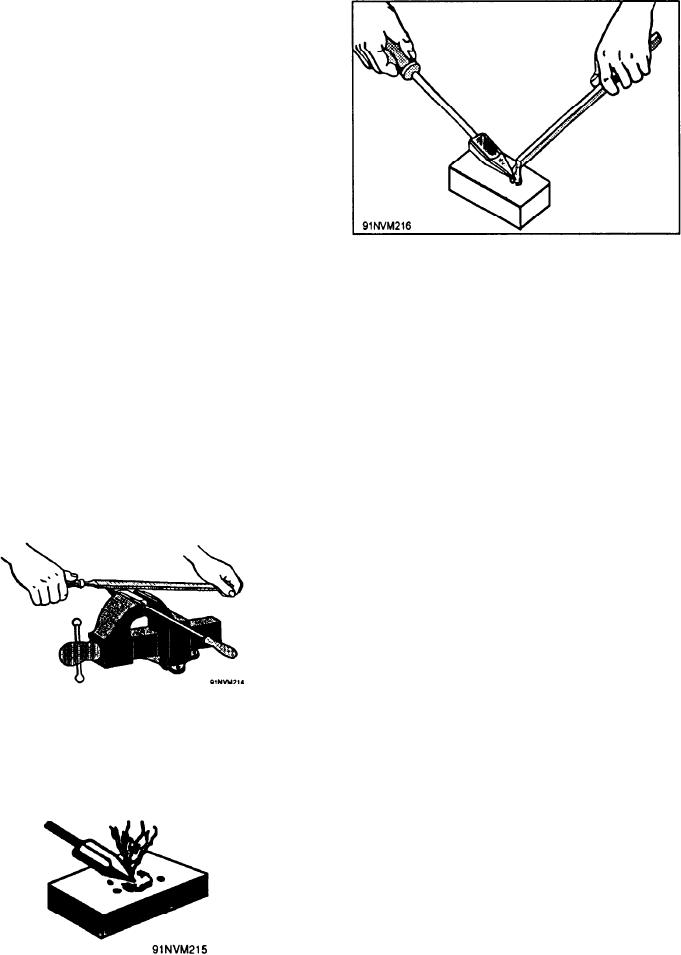

2. Clamp the bit in a vise, as shown in figure 9-24.

3. File the bit with a single-cut bastard file. Rear

down on the forward stroke, and release pressure on the

return stroke. Do not rock the file. Continue filing the

tapered sides of the bit until they are bright and smooth.

Figure 9-26.--Tinning a copper (solder placed directly on

CAUTION: Remember that the bit is hot! Do not

copper).

touch it with your bare hands.

4. Smooth off the point of the bit and smooth off

any sharp edges.

7. Apply solder to the bit until it is tinned. The

solder may be rubbed directly on the bit or it may be

5. Reheat the bit so that it will be hot enough to

placed on the cake of sal ammoniac.

melt the solder.

If sal ammoniac is not available, use rosin. Dip the

6. Rub each filed side of the bit back and forth

filed bit into a container of rosin, then apply the solder

across a cake of sal ammoniac, as shown in figure 9-25.

as shown in figure 9-26.

Commercially prepared soldering salts may also be

used to tin soldering bits. These salts are available in

powder form. Dissolve the powder in water to make a

solution, following the directions that accompany the

material. Dip the soldering bit into the solution, and then

apply the solder.

Cleaning Soldering Bits

Soldering bits should be cleaned just before they are

used. Sal ammoniac is usually used for this purpose.

Rub the copper on a cake of sal ammoniac or dip it into

a container of powdered sal ammoniac. Wipe it clean

with a cloth to remove all grams of sal ammoniac.

Figure 9-24.--Filing a soldering copper.

Another way to clean soldering bits is to dip the bit in

a solution made by dissolving a small amount of sal

ammoniac in water.

SOLDERS

Occasionally, antimony, silver, arsenic, or bismuth are

added to give special properties to the solders. Solders

used for joining aluminum are usually alloys of tin and

zinc or of tin and cadmium. As mentioned before, soft

Figure 9-25.--Tinning a copper (solder placed on a cake of

sal ammoniac).

solders have melting points below 800F and below the

9-25