the lathe and the spline section is separated. The part is

overlayed should be free of all rust, oxides, or grease

now ready for the powdered metal overlay deposit.

and oil. The surface may be machined, filed, or cleaned

with emery cloth to ensure that it is clean.

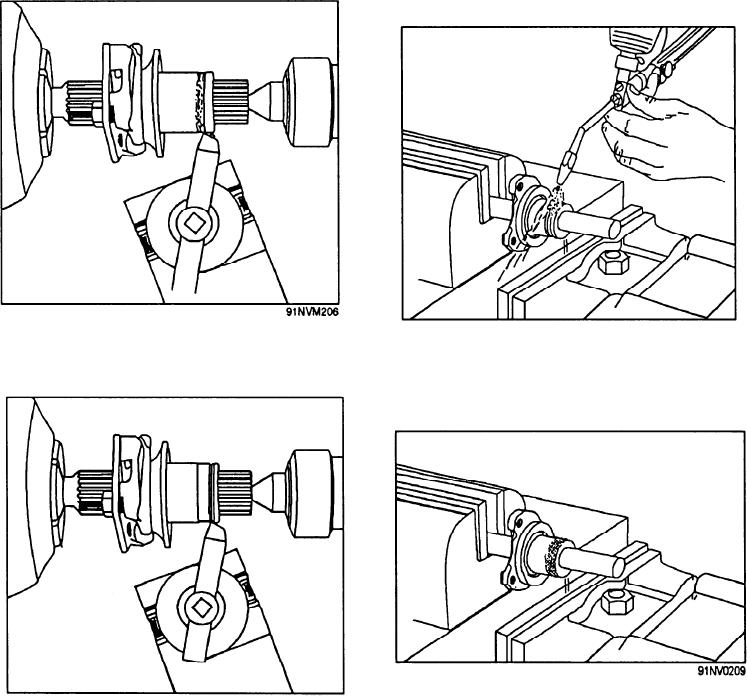

The hollow shaft is slipped over a suitable mandrel

or other similar device for hand turning (fig. 9-18). The

Figures 9-16 through 9-21 show repairs being made

best position of the shaft is horizontal, but the deposit

to an output shaft using the powdered metal torch. The

can also be made with the shaft in the vertical position.

assembled output shaft unit is chucked up in a lathe as

true as possible. The thinnest possible machine-cut is

The oxygen and acetylene pressures used should be

then made to remove the plating in the scored seal area

those recommended by the manufacturer for the tip you

only (fig. 9-16). All grease, contaminants, and other

are using. Use a neutral flame with a slight feather so

foreign matter have been removed with a good solvent.

that when the powder feed lever is depressed a true

A finished preparation lathe-cut of the scored area is

neutral flame is formed. Keep a minimum distance of

then made (fig. 9-17). The unit is then removed from

one-fourth inch between the flame cone and the work.

Figure 9-16.--Removing plating from the scored area of an

output shaft.

Figure 9-18.--Making a powdered metal overlay deposit.

Figure 9-17.--Final lathe-cut being made prior to making an

Figure 9-19.--Completed overlay deposit cooling prior to

overlay deposit.

machining.

9-21