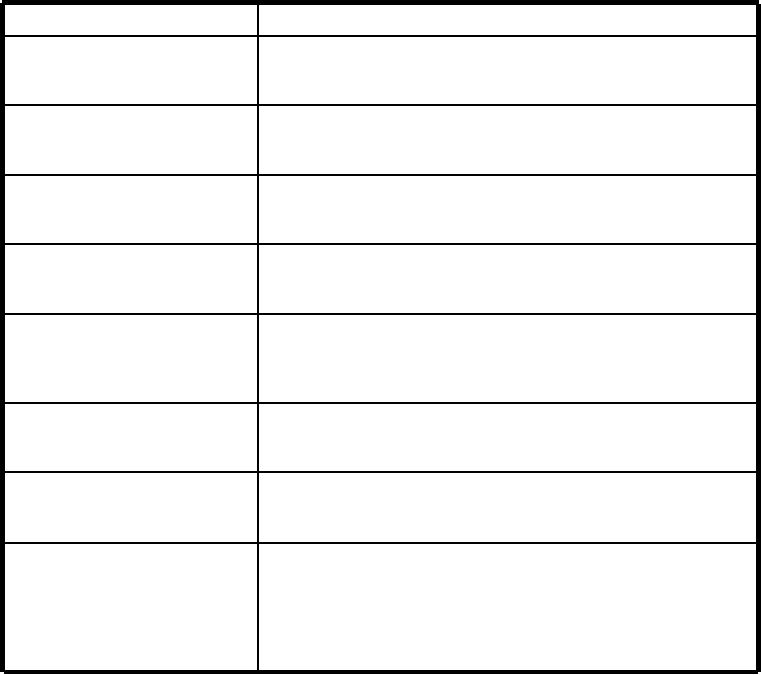

Table 9-6.--Powdered Metal Alloys and Some of Their Uses

General Uses

Powdered Metal Ahoy

Abrasion-resistant nickel-base ahoy for steel, stainless, nickel-base

Hardness:

BOROTEC

alloys and cast irons. Corrosion resistant. Good hardness at high

RC 55-62

temperature. Low coefficient of friction. Nonmachinable.

10009

Ahoy for a thin, rough surface that will abrade, grip, or resist.

GRITALLOY

Tungsten

Uniformly distributed tungsten carbide grit firmly anchored in a hard,

carbide

corrosion-, and heat-resistant nickel-base matric. Nonmachinable.

10011

Cobalt-base ahoy overlay for steel, stainless, cast iron, and nickel

Hardness:

COBALTEC

RC 46-52

alloys. Corrosion and abrasion resistant. Holds hardness at high heat.

Low coefficient of friction.

10091

Hardness:

Severe abrasion-resistant ahoy overlay for steel, stainless steel, cast

TUNGTEC

iron, and nickel alloys. Tungsten carbide particles held in a nickel-base

RC 57-64

matrix. Nonmachinable.

10112

Tensile

High-strength, machinable ahoy for joining steels, copper, and

BRONZOTEC

high-melting copper alloys. Copper-base ahoy deposits offer good

Strength:

corrosion resistance and electrical conductivity. For fillet forming and

10146

65,000 psi

poor fit-up.

Tensile

High-strength, joining ahoy for copper and copper alloys. Copper-base

CUPROTEC

Strength:

ahoy with good corrosion resistance and excellent electrical

42,000 psi

conductivity in joints of proper clearance.

10180

BRONZOCHROM Hardness:

Abrasion-, corrosion-, and heat-resistant nickel-base ahoy overlay for

RC 36-42

steel, nickel alloys, cast iron, and stainless. Crack-resistant deposits, for

10185

both overlaying and joining, are machinable.

STAINTEC

Tensile

High-strength, corrosion-resistant nickel-base ahoy for joining or

Strength:

cladding steels, stainless, cast irons, and nickel alloys. Excellent

machinability.

10670

70,000 psi

Hardness:

RC 80-90

tip will cause the torch to backfire; the weld deposit will

the optimum bonding and wetting of the deposit with

be blown away, and the torch tip may be damaged.

the surface of the workpiece.

These powders are contained in a bellows module

Cooling water is circulated around the tip of the torch,

preventing reflected heat from affecting it. This torch is

that locks directly into the torch. The unique bellows

action helps the flow of the powder through the torch.

often used to surface valve seats where the seat cannot

be removed from the valve body.

The modules are capped when not in use to prevent

contamination from moisture or foreign matter.

POWDERED METALS

SETTING UP THE POWDERED

Powdered metals are available to cover a wide

METAL TORCH

variety of applications. Table 9-6 contains some of the

different powders developed by the Eutectic Welding

Alloys Corporation. The ahoy chemistry and particle

When you assemble the powdered metal torch,

size of each powder assures complete metal-melt during

hand tighten the large threaded nut on the mixing

passage across the torch flame. It also makes certain of

chamber onto the torch body. (Synthetic O-rings are

9-19