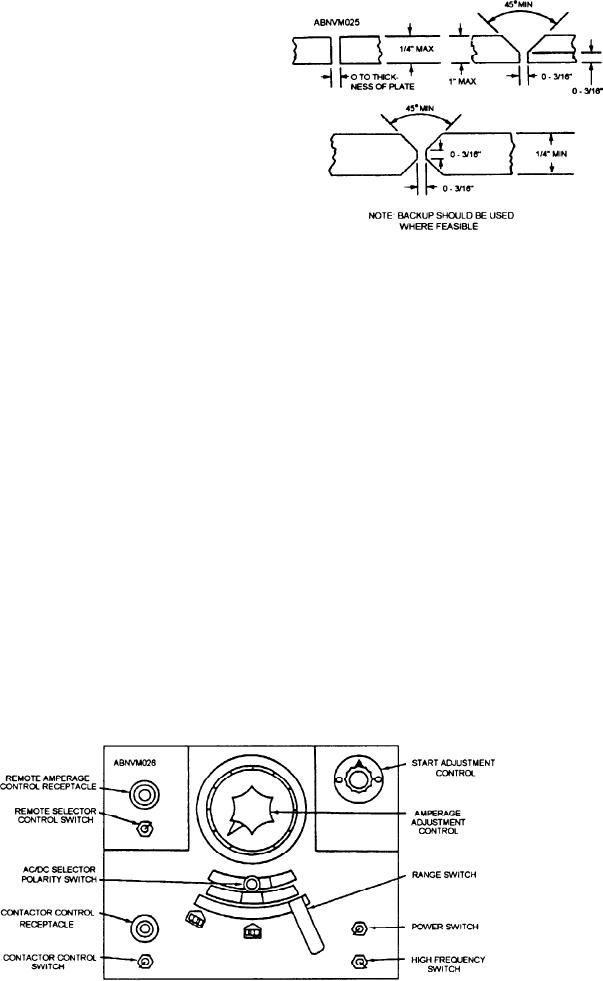

single-vee groove or a double-vee groove, as shown

in figure 10-24. The edges of tubular sections are

prepared the same as the edges of plate of

corresponding thickness.

The welding of tubular sections employs the

same techniques as those used for plate and pipe,

with the exception that a backup is not used when

welding is to be done from both sides. In this case,

the back-chipping technique is used to ensure

high-quality welds in the finished product. Backup

plates are recommended wherever possible to

control weld penetration. These plates also permit

faster welding speeds.

Figure 10-24.--Single-vee and double-vee groove welds.

Good joint fit-up makes welding easier, saves

filler metal and shielding gas, and helps to assure

and a bare filler rod of suitable alloy is manually

quality welds. If jigs are not used to hold the joint

added to the molten pool. Welding can be done

members in their correct position, tack welding may

rapidly from all positions. No flux is required in

be necessary. Tack welds should be short in length,

GTA welding because the action of the arc breaks

one-fourth to one-half inch. They should also be

up the oxide film and allows good weld-metal flow.

small in size, one-eighth to three-sixteenths inch,

A shield of gas, either argon or helium or a mixture

depending upon the size of the metal. In addition,

of argon and helium, surrounds the electrode and

tack welds should be sufficient in number and

the weld pool to prevent oxidation during welding.

correctly placed to maintain proper alignment of

units or components being welded. The number of

Since the heat of the tungsten arc is

tacks to be made is determined by the workpiece to

concentrated in a small area, it is much faster than

be welded.

oxyacetylene welding. Distortion in GTA welds is

also appreciably less than for oxyacetylene welds.

GAS TUNGSTEN-ARC (GTA)

WELDING PROCESS

Welding Power Source

The GTA process is widely used for welding

The heat for any arc-welding process is

relatively thin aluminum sections. In this process,

generated by the arc between the electrode and the

an arc is established between a nonconsumable

base metal. The welding current for GTA welding

tungsten electrode and the aluminum parts to be

is supplied by the ac/dc transformer-rectifier welder

welded with a shield of gas enveloping the arc and

weld pool. The arc melts the aluminum base metal,

( f i g . 10-25). This machine will deliver ac

Figure 10-25.--Equipment for GTA welding.

10-25