The second arc function is to break up and remove

for various ranges of welding current are shown in

the surface oxides from the aluminum. This is

table 10-7.

called the "cleaning action," and takes place during

that part of the ac cycle when the electrode is

We will not describe in detail the advantages

positive. The cleaning action is either a result of

and disadvantages of the various types of electrodes

the electrons leaving the base plate or the gas ions

made of pure tungsten, thoriated tungsten, or

striking the surface or a combination of both.

tungsten-zirconium alloy. Many welders prefer pure

tungsten for GTA welding with ac. Thoriated

Shielding Gas

tungsten is preferred for automatic GTA welding

using dc straight polarity current. A note of interest

Initially the arc breaks up the oxide on the area

here is that tungsten electrodes are usually

where it is directed. The gas shields the arc and

color-coded on one end. A medium green indicates

weld pool, preventing oxidation from reoccurring.

that the rod is pure tungsten. A yellow color

The gas also shields and prevents oxidation of the

indicates a 1 percent thoriated tungsten rod. A light

hot tip of the tungsten electrode; and because of

red color indicates a 2 percent thoriated tungsten

this, the flow of gas should not be stopped until the

rod. A tan color indicates that the rod is zirtung

tungsten electrode tip has cooled. Shutoff can be

(tungsten zirconium).

either manual or automatic; the latter is preferred.

Another function of the gas shield is to provide a

The gas cup or nozzle of the torch can be either

more easily ionized path, thus aiding smooth

ceramic or metal. Ceramic nozzles are generally

transfer of current. Either argon or helium can be

unsatisfactory for welding at high-current levels

used for shielding the arc in the GTA process.

because the nozzle may melt at the tip and partially

Helium requires a higher gas flow, but gives greater

close the orifice. On the other hand, metal nozzles

penetration and faster welding speeds than argon.

of too small diameter will short out the

This deeper penetration is obtained because the arc

high-frequency current if the work is touched by the

nozzle. Torch manufacturers usually recommend

in the helium atmosphere is hotter than in the argon

atmosphere. Argon is preferred by most welders

the type and size of nozzle for different current

because the cleaning action is greater and the arc

ranges. Generally, the nozzle diameter should be

more stable. The flow of gas necessary for good

equal to or slightly greater than the molten weld

GTA welding depends on the welding current, size

pool.

of nozzle, joint design, speed of welding, and

freedom from draft in the area where the welding is

Dual Action of the AC Arc

being done. This last factor can affect gas coverage

considerably. Recommended gas flows are shown in

The first function of the ac arc is to provide the

table 10-8.

heat necessary to melt the base and filler metals.

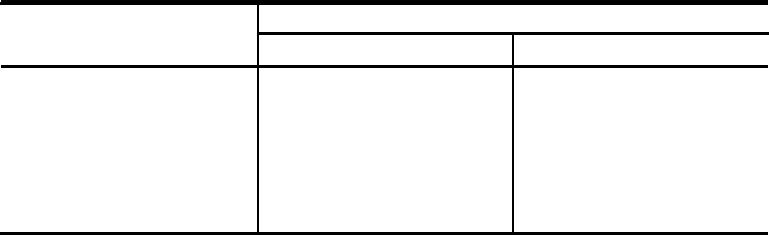

Table 10-7.--Recommended Current Ranges for Thoriated and Nonthoriated Tungsten Electrodes

Current, Amperes

Electrode Diameter Inches

Standard Tungsten Electrodes

Thoriated Tungsten Electrodes

15-80

0.04

10-60

40-120

60-150

l/16

140-250

3/32

100-160

150-210

225-350

1/8

300-450

190-275

5/32

250-350

3/16

400-550

300-490

500-800

l/4

450-600

5/16

10-28