high-frequency, dc reverse polarity (DCRP), and dc

straight polarity (DCSP) welding current. Except

for high frequency, ac welding is only authorized for

use on tenders and shore facilities. Exceptions will

require approval.

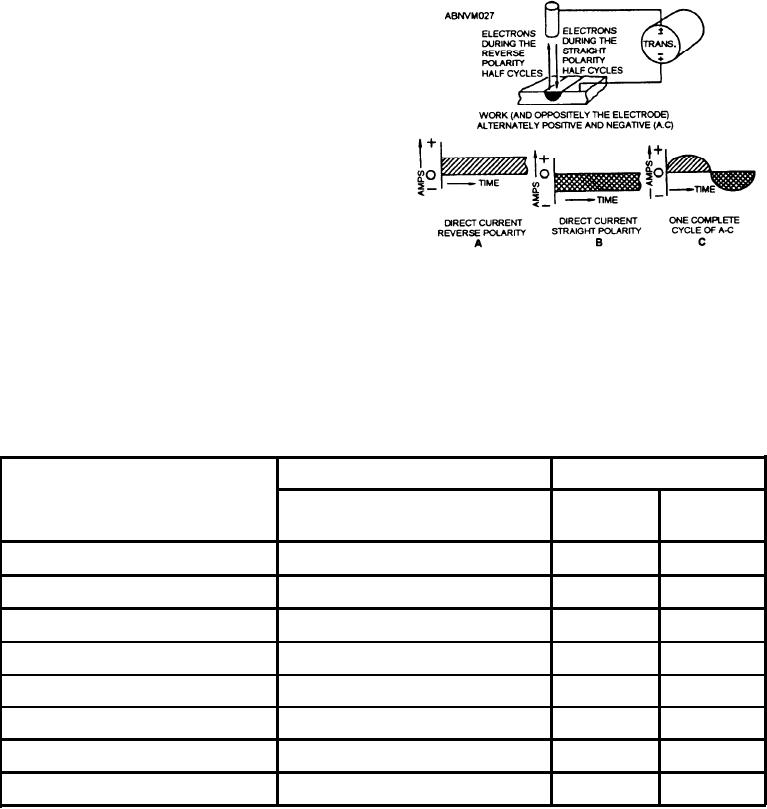

High-frequency ac is recommended for the

welding of aluminum. It offers both the advantages

of DCSP and DCRP welding. Theoretically, ac

welding can be called a combination of DCSP and

DCRP welding, as shown in figure 10-26.

In ac welding, when the current passes through

zero (fig. 10-26), the arc is broken. To restart the

arc, a high-voltage, high-frequency, low-power

additional current is used. This establishes an

ionized path for welding current to follow, when the

Figure 10-26.--Ac welding as a combination of dc straight

and reverse polarity welding.

arc is struck at zero current.

may be used as a guide for the selection of current

In any GTA welding operation, selection of the

for welding some of the more common metals.

proper current is of utmost importance. Table 10-6

Table 10-6.--Current Selection for GTA Welding

Direct Current

Alternating Current

Material

Reverse

with high frequency stabilization

Straight

Polarity

Polarity

Aluminum-up to 3/32 inch thich

1

2

N.R.

Aluminum-over 3/32 inch thich

1

N.R.

N.R.

N.R.

N.R.

1

Aluminum castings

Brass alloys

2

1

N.R.

N.R.

N.R.

1

Silicon copper

Monel

2

1

N.R.

Stainless steel

2

1

N.R.

Hard surfacing alloys

2

1

N.R.

Key: 1. Excellent Results

2. Good Results

N.R. Not recommended

10-26