skin should never be exposed to the rays of the

welding arc because painful burns may result.

If you are teaching a person how to set up the

equipment, you should demonstrate turning on the

water and gas supply, switching on the transformer,

presetting the gas flow and current range, and then

shutting down the equipment. You should then

have the person repeat the start-up and shut-down

procedures until the procedures are thoroughly

understood.

Establishing an Arc and

Forming a Weld Pool

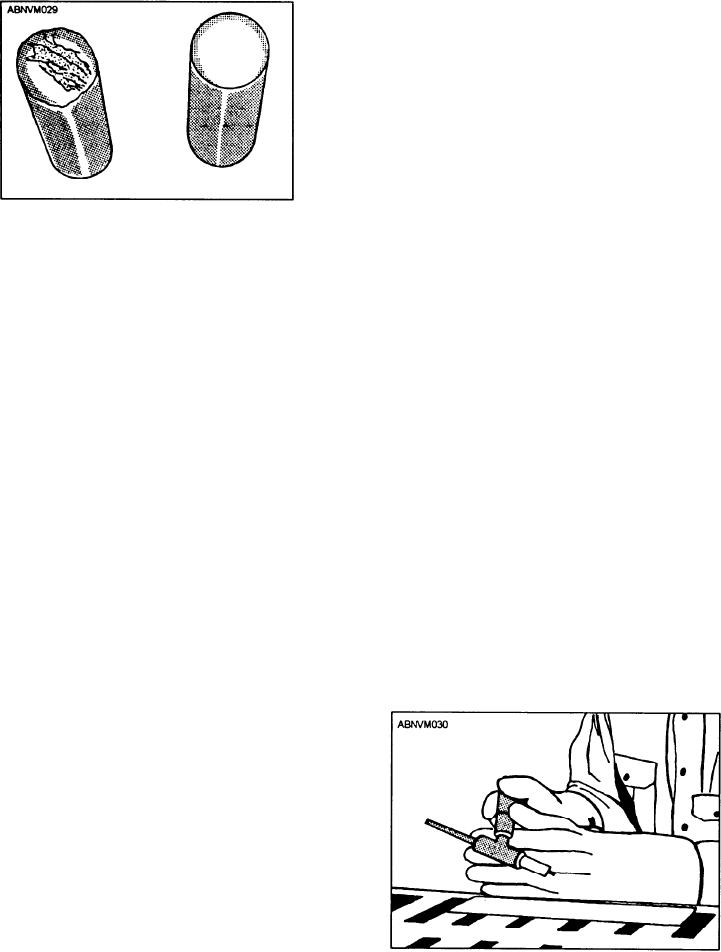

Figure 10-28.--Contaminated and good tungsten electrodes.

This exercise is intended to acquaint you with

the correct technique of initiating an arc and

3. Check the connections on the gas supply for

leaks with soapy water.

forming the weld pool.

4. Select the proper gas cup size according to

As material for this exercise, 1/4" by 6" by 12"

the torch manufacturer's instructions. Make sure

plate of any aluminum alloy recommended for

the gas cup is free of spatter. Clean or replace it if

welding may be used. You will need a standard ac

necessary.

transformer, GTA welding torch equipped with

5/32-inch diameter tungsten electrode, argon gas,

and necessary accessories. The procedure calls for

5. Check the ground cable connections to the

workpiece.

The connections should also be

regulating the argon gas flow 30 to 35 cubic feet per

periodically checked after welding begins, as they

hour. Also, select a welding current of 175 to 225

tend to work loose. This causes the welding current

amperes.

to vary.

When using ac high-frequency current, the

6. Preset the current range (see table 10-7) for

electrode does not need to come in contact with the

t h e joint to be welded, and switch on the

workpiece to strike the arc. The high-frequency

transformer, as shown in view A of figure 10-25.

current will jump the gap between the tungsten

electrode and the workpiece and establish the

7. Open the main shut-off valve on the cylinder

welding current path. To strike the arc, hold the

of gas and adjust the flow, as shown in view B of

torch in a horizontal position, as shown in figure

figure 10-25. Table 10-8 lists the recommended flow

10-29, about 2 inches above the work surface.

for various welding currents.

8. Be sure the water supply to be used is not at

a higher pressure than that recommended by the

torch manufacturer. If satisfactory, the water

shut-off valve is usually opened fully and the flow is

controlled by the water ports in the gun.

9. Never look at a welding arc without a hand

shield or welding helmet with the proper shade of

protective glass, or your eyes will be injured. Eye

fatigue indicates a different shade of glass is

required or there is leakage around the protective

filter glass. A No. 10 glass is satisfactory for most

GTA welding at current ranges of 75 to 200

amperes. Gauntlet gloves and protective clothing

Figure 10-29.--Torch position for the starting swing to strike

must be worn as protection from hot metal. Bare

the arc.

10-31