When using dc straight or reverse polarity

welding current, the same motion is used for striking

the arc, but the electrode must come in contact with

the workpiece to start the flow of welding current,

unless the dc welder has high frequency to give it a

self-starting arc. When the arc has been struck,

withdraw the electrode approximately one-eighth

inch from the work surface to avoid contaminating

the electrode with the molten metal. To make the

weld bead, follow the same steps as described for ac

welding.

To stop an arc, snap the electrode quickly back

to the horizontal position. This must be done

rapidly so the arc will not damage the weld surface

or the workpiece.

You will find that welding technique improves

when you learn to weld in a comfortable position.

Quality welding is dependent upon smooth, even

manipulation of the torch and filler rod. This

cannot be accomplished if you are in an awkward or

uncomfortable position.

A common mistake often made by new

operators in GTA welding is improperly feeding the

filler rod into the arc. The arc heat should be used

to form and hold the molten pool, and the filler rod

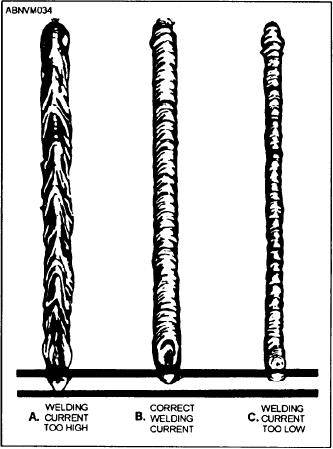

Figure 10-33.--Comparative GTA weld beads as determined

should be melted by the leading edge of the pool.

by electrical current.

In this way, the weld metal will always be fused into

the base metal of the workpiece. By watching the

Good weld bead appearance resulting from

edges of the weld pool, you can learn to judge the

using two different techniques of torch-filler rod

pool's fluidity, buildup, and fusion into the parent

manipulation is shown in figure 10-35. In view A, a

material. Incorrect torch angle, improper torch

bead was made using a two-step technique, namely,

manipulation, too high a welding current, or too low

intermittent filler rod addition to the weld pool and

a welding speed can cause undercutting in the base

intermittent torch movement. In view B, a bead was

plate along one or both edges of the weld bead.

made by moving the torch forward in a relatively

steady motion, feeding the filler rod intermittently

The surface appearance and etched cross

as the pool required it. This latter technique gives

sections of three weld beads on a flat plate are

improved weld bead appearance needing little or no

shown in figure 10-33.

finishing.

The welding current employed in each weld

You should practice making weld beads on a flat

determines its quality. The weld bead shown in

plate until you are satisfied with the workmanship.

view A indicates that the current selected for

In making satisfactory beads, practice is necessary to

welding is too high; view B indicates that the

develop a "steady hand." If the appearance of weld

welding current used is correct; and view C indicates

beads made are equivalent to the ones shown in

that the welding current is too low.

figure 10-36, and the sample proves satisfactory by

visual examination, you should continue on to the

Weld beads made with sufficient and insufficient

next exercise. Should the sample show evidence of

shielding gas are shown in figure 10-34. Insufficient

poor or careless workmanship with poor bead

shielding gas gives an unsound weld bead having a

appearance, spatter, or cracks, as indicated in figure

very poor appearance. Using too much shielding

10-37, you must practice until you make a weld bead

that will meet visual inspection requirements.

gas is wasteful.

10-33