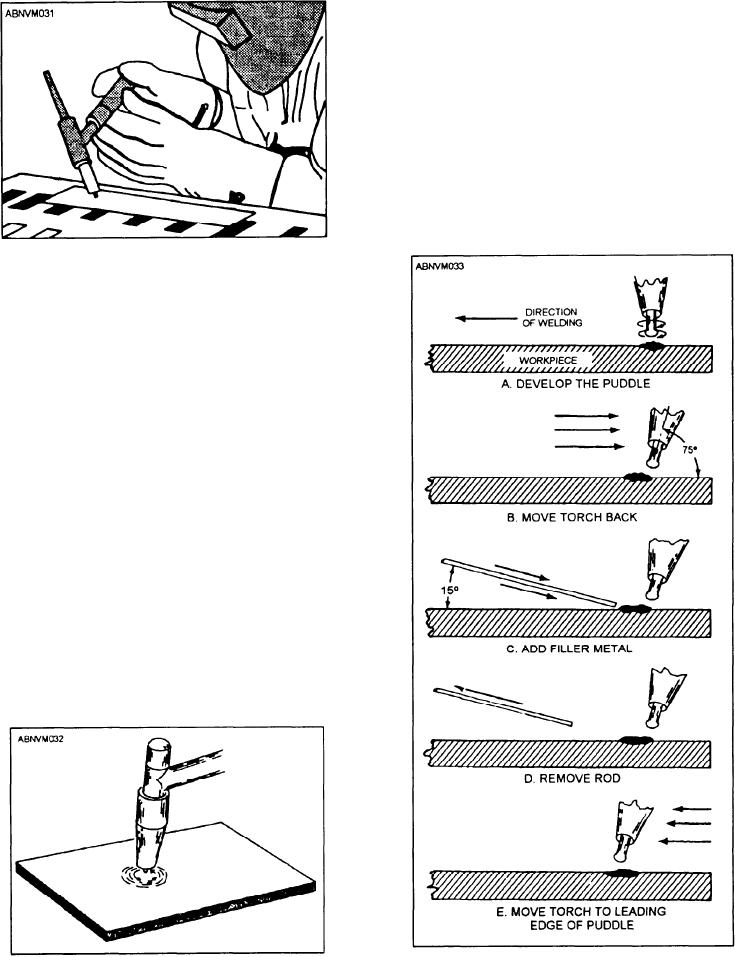

paragraphs. When the puddle becomes bright and

fluid, move the arc to the rear of the puddle and

add the filler metal by quickly touching the rod to

the front edge of the puddle. When the puddle

becomes bright and fluid again, repeat these steps.

Figure 10-32 shows the correct procedure for adding

filler metal. This sequence is continued until the

weld joint has been completed. The width and

height of the weld bead is determined by the speed

of travel, movement of the torch, and amount of

filler metal added.

Figure 10-30.--Position of the torch at the end of the swing

when the arc strikes.

Then, with a rapid motion, swing the electrode end

of the torch down to within an eighth of an inch of

the work surface. The arc will then strike. Figure

10-30 shows the torch position at the time the arc

strikes. After the arc has been struck, hold the

torch at a 90-degree angle to the workpiece surface

and with small circular motions, as shown in figure

10-31, form a molten puddle. When the molten

puddle has been formed, hold the torch at a

75-degree angle to the work surface and move the

torch slowly and steadily along the joint at a speed

that will produce a bead of uniform width. Move

the torch slow enough to keep the puddle bright and

fluid. No oscillating or other movement of the

torch is necessary except the steady forward

movement.

When the use of a filler metal is necessary, form

the molten puddle as described in the previous

Figure 10-32.--Addition of filler metal (flat position).

Figure 10-31.--Forming a molten puddle with a GTA torch.

10-32