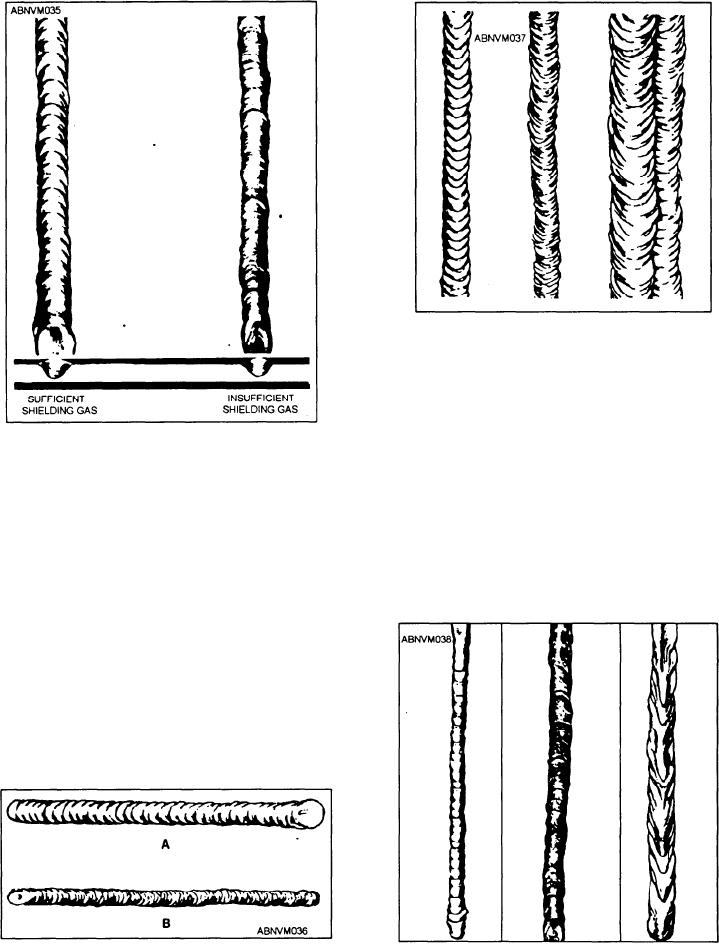

Figure 10-36.--Visual inspection standards for GTA welds.

course, you will need the ac transformer, argon gas,

and necessary accessories.

The procedure for welding is to bevel abutting

Figure 10-34.--Comparative GTA weld beads as determined

edges of sheet as indicated in figure 10-38. Clean

by shielding gas.

all surfaces, including the backing strap, with

solvent, and wipe dry. Brush the weld surface areas

Flat-Position Single-Pass Butt Welds

with a stainless-steel wire brush. Inspect and clean

the filler rod if necessary. Regulate the argon gas

This exercise will help you learn the technique

flow 25 cubic feet per hour, and select a welding

of making a single-pass butt weld in the flat position

current of 175 to 210 amperes. Arrange the plates

on aluminum. You should use 3/16" by 6" by 12"

EC aluminum and 1/8-inch diameter 1100 alloy filler

rod, or any other recommended combination of

parent sheet-filler alloy. You will also need a 3/16

by 1" by 12" backing strap of EC aluminum or the

same sheet-filler alloy.

The GTA welding torch should be equipped

with a l/8-inch diameter tungsten electrode. Of

Figure 10-35.--Comparative GTA weld beads with filler rod

Figure 10-37.--Unacceptable GTA welds.

manipulation.

10-34