welding gun does not contain the spool of filler

metal. The filler metal is on a 12-inch diameter

spool that is inside the canister. The filler metal is

fed through a lo-foot long plastic guide liner to the

drive rolls in the gun and then to the weld area.

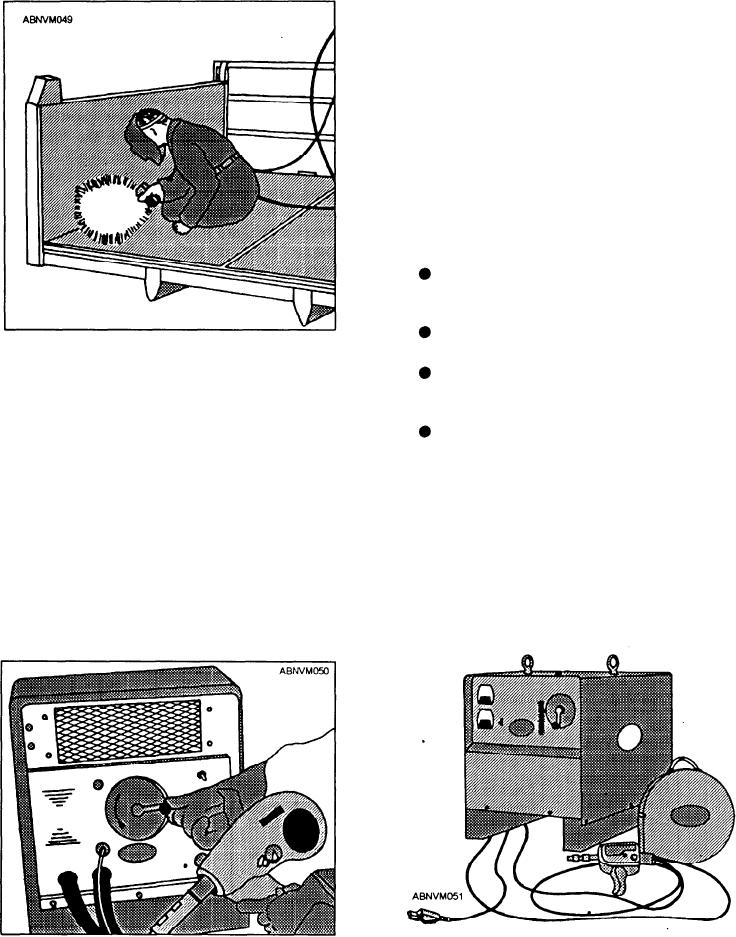

The dc rectifier welders shown in figures 10-49 and

10-50 are connected to a 440-volt ac electrical

supply source. These welders may be used with a

220-volt ac supply source by making the necessary

electrical changes according to the manufacturer's

technical manual.

In addition to the equipment already mentioned,

the following supplies and equipment are needed for

the GMA welding of aluminum:

Gas supply, regulator-flowmeter valve, hose,

and fittings

Filler wire

Figure 10-48.--CMA welding aluminum truck bed.

Helmet or eye shield, and protective

clothing

metal. The welding gun is connected directly to the

dc rectifier welder. This eliminates the need for a

Stainless-steel wire brush

separate control unit and wire drive assembly. Wire

filler metal in sizes 0.030, 3/64, and l/16 inches may

DCRP is most often used for GMA welding of

be used with this gun. The weight of the gun,

aluminum. In DCRP welding, the electrons flow

including a l-pound spool of wire, is about 3

from the plate to the filler wire. This provides the

pounds.

heating effect necessary on the end of the filler wire

electrode to form molten aluminum droplets. These

Another GMA welding unit is shown in figure

droplets, in turn, are transferred into the weld pool.

10-50. It consists of a 250-amp dc rectifier welder,

The GMA process deposits filler metal at higher

the welding gun, and a canister. This equipment

rates than the GTA process, making faster, more

differs from that shown in figure 10-49 in that the

Figure 10-50.--Heavy-duty GMA welding equipment (AIRCO

Figure 10-49.--GMA welding equipment (AIRCO products).

products).

10-39