Helium, argon, or mixtures of the two are

economical welds with less heat effect on the

suitable for GMA welding of aluminum. At any

workpiece.

given current, the helium shielded arc has a higher

voltage than the argon arc. A smoother, more

Dual Action of the Arc

stable arc is obtained with argon. Pure argon is

used most widely on aluminum plate less than

The reverse polarity arc supplies heat to melt

three-fourths inch thick. Combinations of argon

the consumable filler wire and the workpiece. The

and helium are often employed for welding heavy

arc also breaks up the surface oxide on the

plate. This combination is used particularly for

aluminum. This cleaning action is due to the

out-of-position welding to obtain the "hotter arc"

electrical characteristics of the DCRP arc. Arc

characteristics of helium with the stabilizing effects

action is not intermittent as in ac GTA welding, but

of argon. Mixtures of 75 percent helium and 25

is continuous because there is no change in current

percent argon are commercially available. Other gas

direction using dc GMA welding.

mixtures, for example, 60 percent helium and 40

percent argon, are mixed by combining flows from

Shielding Gas

separate tanks of helium and argon. Helium

additions of over 10 percent markedly change the

The GMA welding gun deposits molten

arc characteristics.

aluminum where directed on the workpiece. The

gas shields the arc and weld pool while the filler

The flow of gas necessary for good quality GMA

wire is being melted and transferred in spray or

welding depends upon the gas used, welding current,

droplet form to the pool. Another purpose of the

diameter of gun nozzle, joint design, welding

gas shield is to provide a more easily ionized path

position, speed of welding, and freedom from draft

than air.

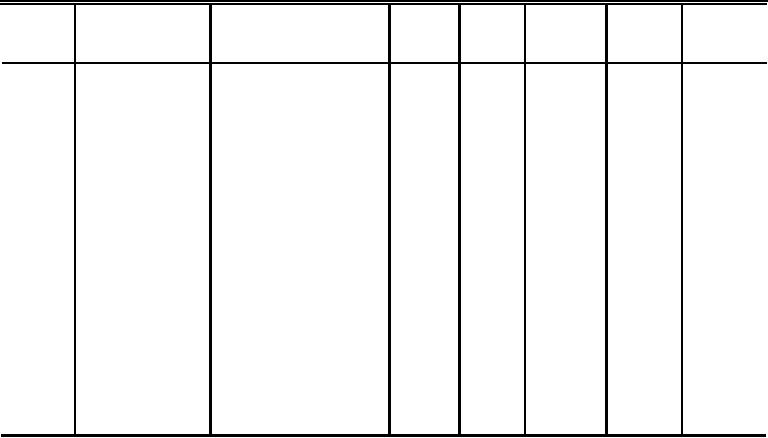

Table 10-9.--Recommended Practices for GMA Welding of Aluminum Alloys

Argon (2)

Filler

Current

Material

Joint Degree (1)

No. of

Amps

Wire Dia.

Gas Flow

Welding Position

Arc

Thickness

Passes

Inches

CFH

DC

Voltage

Inches

30

1

110-130

20

3/64

Flat

None

l/8

100-120

30

1

Horiz. & Vert.

None

20

3/64

40

Overhead

None

100-120

20

1

3/64

200-225

40

1

Flat

None or Single Bevel

l/l6

26-28

l/4

170-190

26-28

l/16

45

2 or 3

Horiz. & Vert.

Single Bevel

50

2 or 3

180-200

26-28

l/16

Overhead

Single Bevel

230-300

50

1 ot 2

Flat

Single or Double Bevel

l/l6

26-28

3/8

Horiz. & Vert.

Single or Double Bevel

180-225

26-28

l/16

50

3

5

Overhead

Single or Double Bevel

200-230

26-28

l/16

50

2 or 3

Single or Double Bevel

280-320

26-30

3/32

50

Flat

l/2

Single or Double Bevel

210-250

26-30

l/16

50

3 or 4

Horiz. & Vert.

Overhead

Single or Double Bevel

225-275

26-30

l/16

80

8 to 10

Single or Double Bevel

320-375

3132

60

4 to 5

1

Flat

26-30

4 to 6

Horiz. & Vert.

Single or Double Bevel

225-275

26-30

l/16

60

Overhead

Single or Double Bevel

225-275

26-30

l/l6

80

15 or more

(3)

2

60

350-425

12 or more

Single or Double Bevel

Flat

26-30

3/32

(3)

3

60

350-450

20 or more

Flat

26-30

3/32

Single or Double Bevel

(l)

See exercises for Joint Designs.

(2)

Gas flows for helium are slightly higher than for argon. Lower flows are possible as mentioned in Part I-Basic Theory.

(3)

Preheat optional.

10-40