you will be able to recognize the sound of the

gas hose across your shoulder to ensure free

proper length of arc.

movement of the welding gun. Hold the gun close

to, but not touching, the workpiece. Lower your

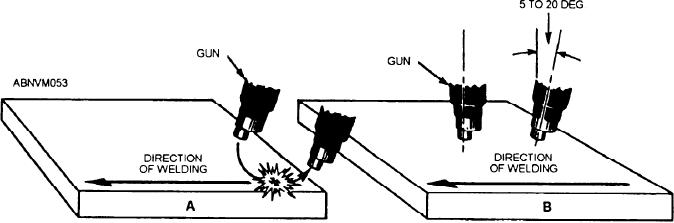

Use the forehand technique for welding. Hold

helmet and squeeze the trigger on the gun.

the gun at an angle of 5 to 20 from the vertical

Squeezing the trigger starts the flow of shielding gas

position, as shown in view B of figure 10-52. A

and energizes the welding circuit. The wire-feed

right-handed person welds from right to left. The

motor is not energized until the wire electrode

forehand technique provides the best coverage of

comes in contact with the workpiece. Move the gun

shielding gas to the weld area, and the operator has

toward the work, touching the wire electrode to the

a better view of the weld joint. A left-handed

work with a sidewise scratching motion as shown in

person holds the gun in the same position relative to

view A of figure 10-52. To prevent sticking, pull the

the surface of the base metal, but welds from left to

gun back quickly, about one-half inch, the instant

right.

contact is made between the wire electrode and the

workpiece. The arc will strike as soon as contact is

You should first learn to strike and establish an

made and the wire-feed motor will feed the wire

arc and to adjust the wire feed and welding current

automatically as long as the trigger is held.

to obtain the proper arc characteristics. Then you

should learn to run a bead. To run a practice bead,

To break the arc, just release the trigger. This

select the proper current setting, gas flow, and

breaks the welding circuit and also de-energizes the

correct size filler wire as recommended in table

wire-feed motor. The wire electrode may stick to

10-9; then, proceed as follows:

the work when you strike the arc, or at any time

during welding. If that happens, release the trigger

1. Hold the gun in the proper position, close to

and clip the wire with a pair of pliers or side cutters.

but not touching the surface of the work, and

squeeze the trigger.

A properly established arc has a soft, sizzling

sound. The arc itself is about one-fourth inch long,

2. Lower your welding helmet and strike the

or about one-half the distance between the gun

arc.

nozzle and the work. If the arc does not sound

right, adjust the wire-feed control dial or the

3. Hold the gun at the starting point until a

welding machine itself. For example, a loud,

puddle forms.

crackling sound indicates that the arc is too short

and that the wire-feed speed is too fast. Correct

4. As soon as you see a puddle, move the gun

t h i s by moving the wire-feed dial slightly

forward steadily at a rate that permits the work and

counterclockwise. This decreases wire-feed speed

the electrode to melt at the same time. Keep the

and increases arc length. A clockwise movement of

arc in the pool of weld metal. Do not direct it into

the dial has the opposite effect. With experience,

Figure 10-52.--GMA welding. (A) Striking the arc. (B) Gun angle.

10-42