and flat appearance of the bead made with excessive

welding current.

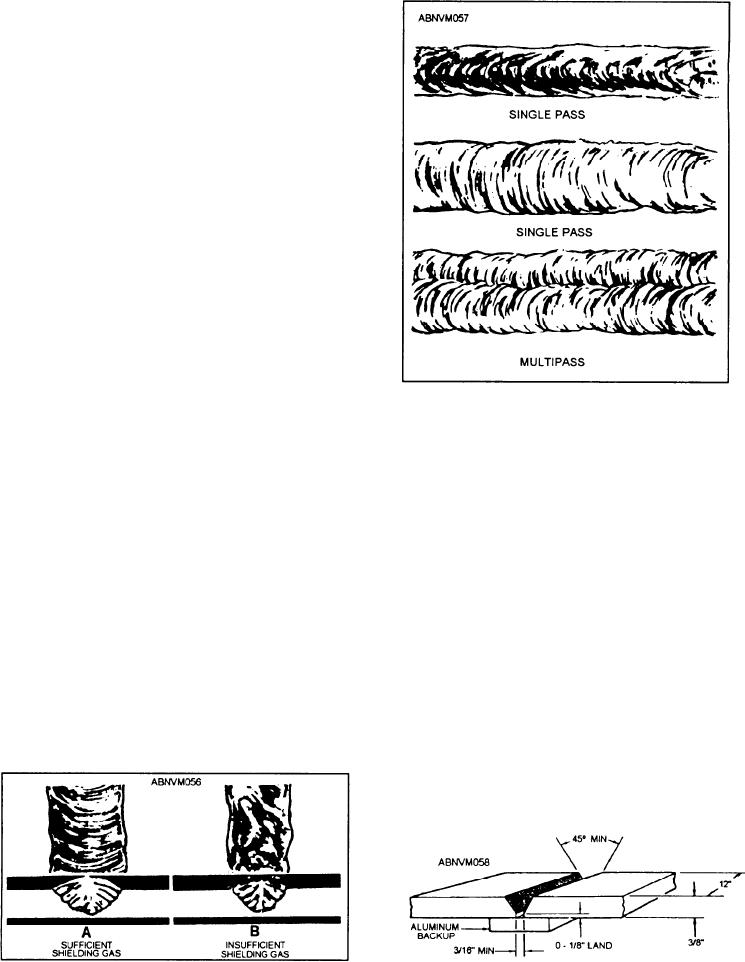

Weld beads made with sufficient and insufficient

shielding gas are shown in figure 10-55. Inadequate

shielding gas gives an unsound weld bead having a

dirty appearance. Using too much shielding gas is

wasteful and may cause weld turbulence and

porosity. Note the appearance and penetration of

the bead made with the proper current and gas flow.

Recommended flows of shielding gas for various

thicknesses of plate are shown in table 10-9.

If the sample weld shows evidence of poor or

careless workmanship, having spatter and cracks, or

has bead appearance as indicated in views A and B

of figure 10-54 or view B of figure 10-55, it is

unsatisfactory. Continue to practice until you can

make a weld that will pass visual inspection.

Practice making weld beads on flat plate until

satisfactory workmanship results. Practice is

necessary to develop a "steady" hand. If the

appearance of your weld beads is equivalent to the

Figure 10-56.--Acceptable single-pass and multipass GMA

o n e s shown in figure 10-56, the sample is

welds.

satisfactory to visual examination.

To be proficient as a welder, you must be able

parent plate-filler wire alloy combination. You will

to make all the various types of welds in the flat,

also need a backing strap 1/4" by 1 1/2" by 12", cut

from the parent plate or thinner aluminum alloy

vertical, horizontal, and overhead positions. The

section compatible with the workpiece. In addition,

following exercises will aid you in learning the

you will need a suitable solvent or cleaner for

techniques employed in making different types of

removing dust or grease.

Use the standard

welds in all positions.

equipment and necessary accessories. Saw or

machine bevel the abutting plate surfaces, allowing

Flat-Position Single-Pass Butt Welds

for land. Thoroughly clean the weld surface areas,

including the backing strap. Regulate the gas flow

This exercise will help you make a single-pass

at 50 cubic feet per hour, and select a welding

butt weld in aluminum plate. You will need 3/8" by

current of 230 to 300 amperes.

6" by 12" EC aluminum plate and l/16-inch diameter

1100 alloy filler wire, or any other recommended

Aluminum plates should be prepared and placed

as shown in figure 10-57. When so placed, there

should be a slight gap between the two aluminum

Figure 10-55.--Weld bead characteristics determined by

Figure 10-57.--Joint design flat-position, single-pass butt

shielding gas.

welds in aluminum plate.

10-44