and equipment are the same as those used for

Vertical-Position Multipass Fillet

horizontal- and vertical-position welding. However,

and Butt Welds

in overhead-position welding, the gas flow is

regulated to flow at 60 cubic feet per hour, and the

This exercise will help you learn vertical-position

welding current is selected at 225 to 275 amperes.

GMA welding. The materials and equipment

needed are the same as those described for

Prepare edge angles of abutting plates by

horizontal-position welding. The gas flow and

machining or grinding as shown in figure 10-44.

current range are also the same. Machine or grind

Clean and thoroughly dry the weld areas, using

the abutting plate edges to the angles shown in

solvent to degrease the metal. Surfaces on which

figure 10-42. Thoroughly clean and dry the weld

weld metal will be deposited should be wire brushed

areas. Clean with a wire brush between passes if

to remove aluminum oxide coating. Brush with a

contamination shows in the weld area.

stainless-steel brush after every pass if there is

contamination. Follow the weld sequence shown in

Follow the weld sequence shown in figure 10-42.

figure 10-44. Figure 10-68 shows a welder making

Make all welds in the upward direction. Take care

overhead multipass fillet and butt welds.

to fit the parts to be welded with the root space

shown.

Here, as in vertical welding, a slight weave may

or may not be used. A lower welding current and

Fillet and butt welds made in the vertical

travel speed are used as compared to flat-position

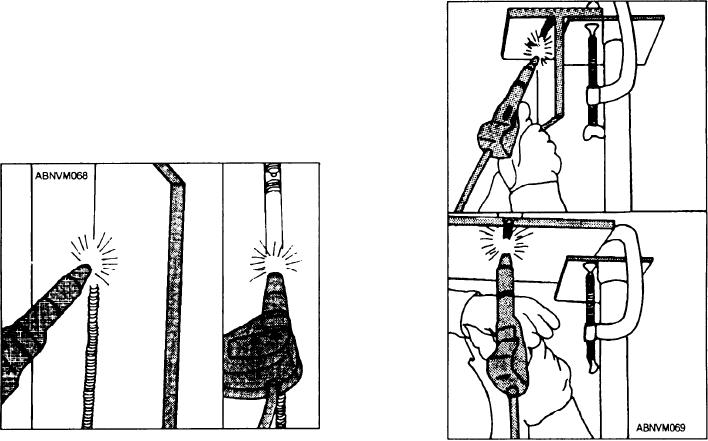

position are shown in figure 10-67. Note that the

welding. Conversely, a higher flow of shielding gas

welding is done upward. All factors concerning

is used. Take extreme care to avoid sagging and

out-of-position horizontal welding also apply here.

poor penetration. Trying to deposit too much metal

Do not use too high a welding current or deposit

and carrying too large a weld pool is the direct

too large a weld bead. If the molten pool is too

cause of such conditions. Most inexperienced

large, the effects of gravity will make it difficult to

welders find overhead welding awkward. Assume as

control. Bead size, weld speed, and bead sequence

comfortable and relaxed a position as possible, and

must be such that there is no lack of fusion between

passes. Some welders find that a slight side-to-side

weave, approximately one-eighth inch, when done

smoothly and evenly, is helpful in vertical welding.

Overhead-Position Multipass Fillet

and Butt Welds

This exercise will help you learn

overhead-position GMA welding. The materials

Figure 10-67.--Welding fillet and butt joints in the vertical

Figure 10-68.--Welding overhead multipass fillet and butt

position.

welds.

10-48