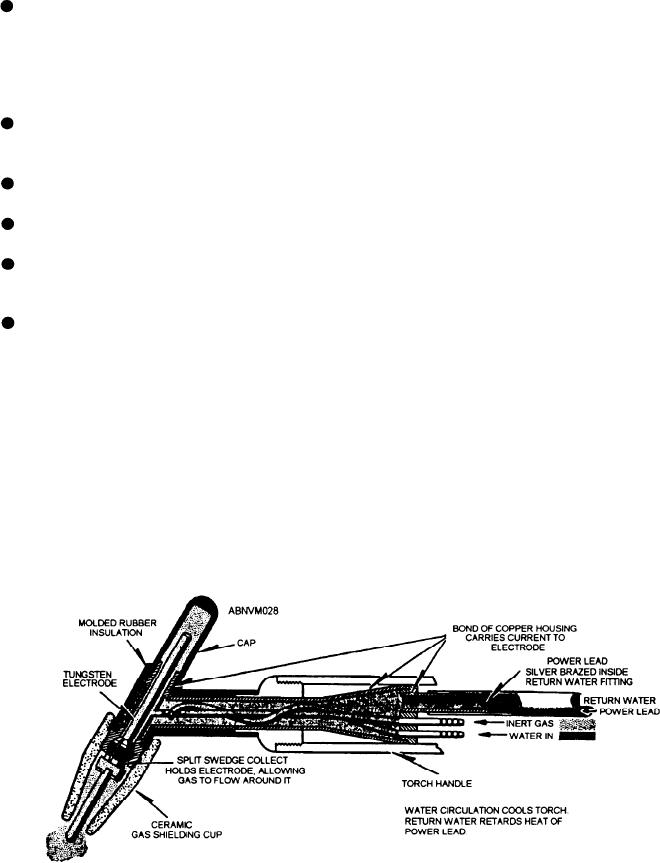

Overheating can melt the silver-brazed metal joints

Welding Equipment and Supplies

in the torch and the plastic water tube that sheaths

the electric cable. A control mechanism is available

In addition to the ac power source, the following

that does not allow the welding current to start

equipment is needed for GTA welding:

unless the water is flowing. Some GTA welding

equipment is provided with a solenoid valve that

GTA welding torch. (Note that the word

automatically shuts off the water supply when the

torch is commonly used for this GTA

welding stops. This prevents excessive cooling and

welding device. It is also termed electrode

moisture condensation inside the torch. Moisture

holder. However, throughout this discussion

can contaminate the electrode and cause porosity in

the word torch will be used.)

the weld during the initial weld period. When GTA

equipment is to be used in the field and if water is

Gas supply, regulator-flowmeter, hose, and

not available, a small water tank and pump can be

fittings

used to circulate water between the tank and the

torch. The GTA welding torch carries the welding

Filler metal

current and directs the gas to the weld area. The

torch must be properly insulated for the maximum

Water supply and fittings

current ranges to ensure operational safety.

Current is transmitted from the ac transformer

Helmet or eye shield, and protective

through the power cable to a collet holding the

clothing

tungsten electrode. Gas ports surrounding the

electrode permit the gas to enter the nozzle or

Stainless-steel wire brush

cup.

For currents above 200 amperes, cooling the

The electrode should extend beyond the end of

torch and power cable is necessary because of heat

the gas cup a distance of l/8 to 3/16 inch. Selecting

generated by the arc and the current passing

the right size electrode for each job is important to

through the cable. For welding currents below 200

prevent electrode damage and poor welds caused by

amperes, air-cooled torches are satisfactory. A

too high or too low a current. Excessive current will

sectional sketch of a GTA water-cooled torch is

cause tungsten particles to transfer to the weld,

shown in figure 10-27.

while insufficient current allows the arc to wander

erratically over the end of the electrode. With

Water used to cool the welding torch should be

correct current the electrode will have a stable

clean to prevent clogging or flow restriction.

hemispherical end. Recommended electrode sizes

Figure 10-27.--Sectional sketch of a GTA water-cooled torch.

10-27