Always use a fine grinding compound to finish

the lapping job.

When you complete the lapping job, spot-in and

grind-in the disk to the seat.

Abrasive compound needed to grind-in and lap-in

valve seats and disks is available in Navy stock in four

grades. The following list shows grades and the

recommended sequence of use:

GRADE

USE

Figure 13-4.--Lapping tools.

has the same angle as the valve seat (fig. 13-4). You will

Coarse

To lap-in seats that have deep cuts and

use the lapping tool and grinding compounds in almost

scratches or extensive erosion.

the same way you used the disk in the grinding process.

However, you NEVER use the valve disk as a lap. The

Medium

To follow up the coarse grade: also

following list shows the essential points you must keep

may be used at the start of the

in mind while using the lapping tool:

reconditioning process where damage

is not too severe.

Do not bear heavily on the handle of the lap.

Do not bear sideways on the handle of the lap.

To use when the reconditioning

Fine

process nears completion.

Shift the lap-valve seat relation so that the lap

will gradually and slowly rotate around the entire

To finish lap-in and do final grind-in.

Microscopic

seat circle.

fine

Check the working surface of the lap; if a groove

REFACING. --The seat of a valve may be so

wears on it, have the lap refaced.

deeply cut, scored, or corroded that lapping will not

Use only clean compound.

correct the condition. If so, you must machine it, or, in

an extreme case, replace it with a new seat.

Replace the compound often.

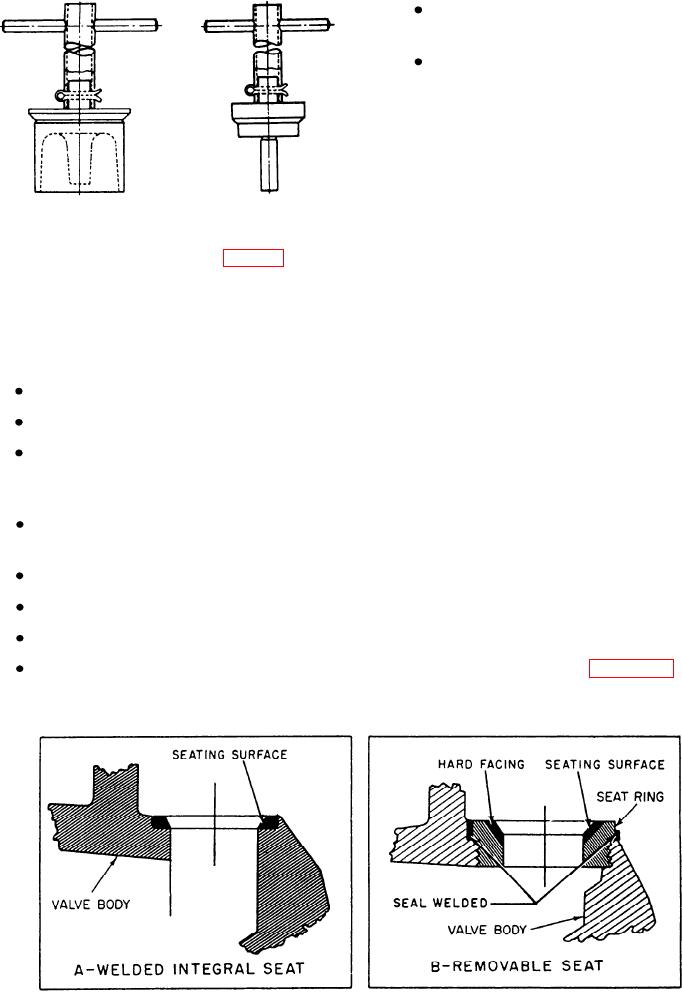

Many valves have removable seats that are

Spread the compound evenly and lightly.

threaded, welded, threaded and welded, or pressed into

Do not lap more than is necessary to produce a

the valve body. In view A of figure 13-5, the valve

smooth and even seat.

seating surface has been welded so that it has become

Figure 13-5.--Valve seat construction.

13-6