pipe in which the valve is installed. Gate valves are not

suitable for throttling purposes because turbulence

makes it difficult to control flow. Also, fluid force

against a partially open gate causes it to vibrate, causing

extensive damage to the valve.

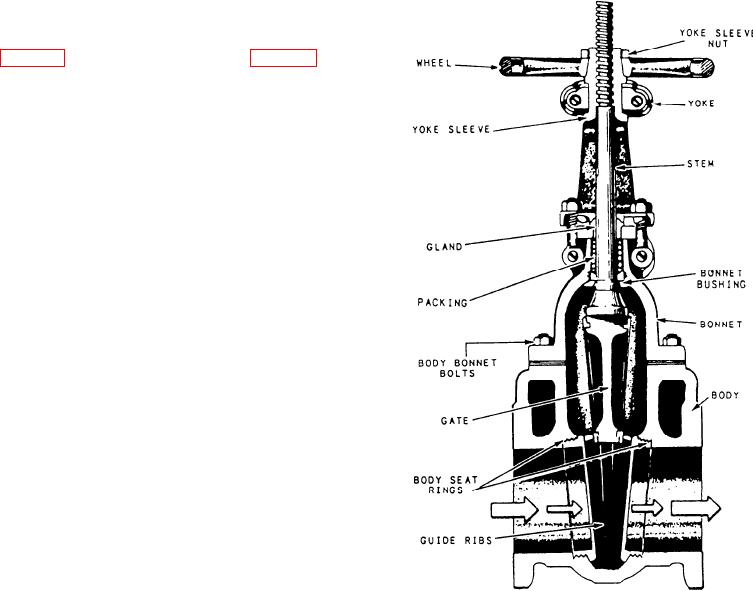

Gate valves are classified as either rising stem

(fig. 13-8) or nonrising stem valves (fig. 13-9). In a

rising stem gate valve, the stem is attached to the gate,

and the gate and the stem rise and lower together as the

valve is operated. In a nonrising stem gate valve, the

stem is threaded on its lower end into the gate. As you

rotate the handwheel on the stem, the gate travels up or

down the stem on the threads while the stem remains

vertically stationary. This type of valve almost always

has a pointer type of indicator threaded onto the upper

end of the stem to show the gate's position.

With this basic information on the principles of the

gate valve, you are ready to learn about repair

procedures and the manufacture of repair parts.

You should use lapping to correct defects such as

light pitting or scoring and imperfect seat contact. Use

a lapping tool designed for the type of valve to be

reconditioned. NEVER use the gate as a lap.

USC the same lapping process for gate valves that

we described earlier for globe valves. But with gate

valves, turn the lap by a handle extending through the

inlet or outlet end of the valve body. Insert the lapping

tool, minus the handle, into the valve so you cover one

of the seat rings. Then attach the handle to the lap and

begin the lapping work. You can lap the wedge gate to

a true surface by using the same lap you used on the seat

rings. In some cases when a gate is worn beyond repair

and a shim behind the seat will not give a proper seat,

you may need to plate the gate or seat.

NOTE: A shim has to be applied behind both seats

Figure 13-8.--Cutaway view of a gate stop valve (rising stem

to maintain the proper angle.

type).

As another alternative, you may weld repair the

damaged gate, then use a mill or lathe with an angle

governor maintains a constant pump discharge pressure

plate or fixture to machine it to its original specifi-

under varying conditions of load. It is installed in the

cations. Plating has one advantage over welding; the

selective brush plating method does not heat the gate.

steam line to the pump. It controls the amount of steam

When you build up metal by welding, it always heats

admitted to the driving turbine, thereby controlling the

the surfaces and can cause loss of temper or other

pump discharge pressure.

weaknesses in the metal.

Two of the most common types of constant-

pressure pump governors used by the Navy are the

Repairing Constant-Pressure

Leslie and the Atlas. The two are very similar in

Governors

operating principles. Our discussion is based on the

Leslie governor, but most of the information also

Many turbine driven pumps are fitted with special

applies to the Atlas governor.

valves called constant-pressure governors. This

13-8