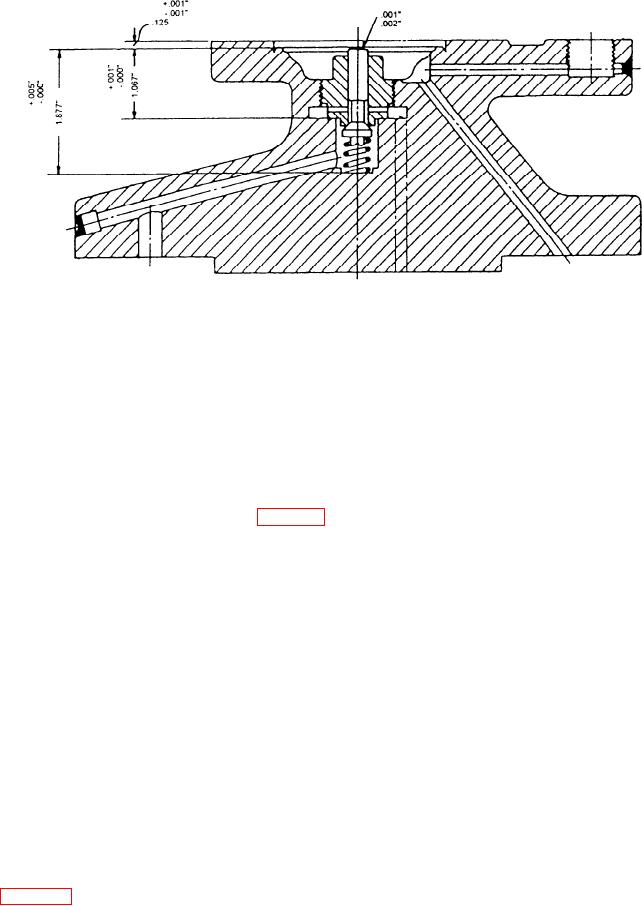

Figure 13-11.--Critical dimensions of the Leslie top cap.

grooves and that the cylinder liner is smooth and free of

When you install the control valve and its bushing,

grooves, pits, and rust.

remember that the joint between the bottom of the

When installing the cylinder liner, be sure the top

bushing and its seat is a metal-to-metal contact. Install

of the liner does not extend above the top of the valve

the bushing tightly, and when it is all the way down, tap

body. The piston must work freely in the liner; if there

the wrench lightly with a hammer, to ensure a

is binding, the governor will not operate satisfactorily.

steam-tight joint.

When the controlling valve is installed, you must

Renew the controlling valve spring and the main valve

check the clearance between the top of the valve stem

spring if they are weak, broken, or corroded, or if they

and the diaphragm. It is absolutely mandatory that this

have taken a permanent set. Renew all diaphragms if

clearance be between 0.001 and 0.002 inch (fig. 13-11).

necessary. If you use the old diaphragms, install them

If the clearance is less than 0.001 inch, the diaphragm

in their original position; do not reverse them.

will hold the control valve open, allowing steam to flow

Follow the instructions in the manufacturer's

to the main valve at any time the throttle valve is open.

technical manual when you reassemble the governor.

If the clearance is more than 0.002 inch, the diaphragm

All clearances must be as designed if the governor is to

will not fully open the control valve. This means the

operate satisfactorily. Check each moving part carefully

main valve cannot open fully, and the unit cannot be

to ensure freedom of movement.

brought up to full speed and capacity.

When you have reassembled the governor, test it as

When the main valve seating area is damaged, it

soon as possible so that you can make any needed

must be lapped in by the same process. ALWAYS lap in

corrections.

the main valve with the piston in the cylinder liner to

Repairing Double-Seated Valves

ensure perfect centering.

If the damage to the seating surfaces is excessive,

On a double-seated valve, the extent of damage

you must install new parts. Use parts supplied by the

determines the kind of repairs you can do. Normally,

manufacturer if they are available.

you can lap it or weld-repair it and remachine it to fit

the body. The normal seat angles are the same as those

TOP CAP.--If the top flange of the top cap of the

in globe valves, and the spotting-in procedure is the

governor becomes damaged, you must be extremely

same. You can hold most valve disks on a spud or mount

careful when you machine it. Consult the manu-

them on a mandrel and cut them the same way as a globe

facturer's technical manual for the correct clearances.

valve. In this case as in the others, it is best to consult

(See fig. 13-11.)

local quality assurance directives and local procedures

All seating surfaces must be square with the axis of

when you repair this type of valve. Also, in most cases

the control valve seat threads and must have the

the blueprints will show ND (no deviations) and must

smoothest possible finish. Before you start the

be closely adhered to, as far as type of weld and quality.

reassembly, be sure that all ports in the top cap and the

In all cases, shop LPO's should be able to provide the

diaphragm chamber are free of dirt and other foreign

necessary information.

matter. Be sure that the piston rings are free in their

13-12