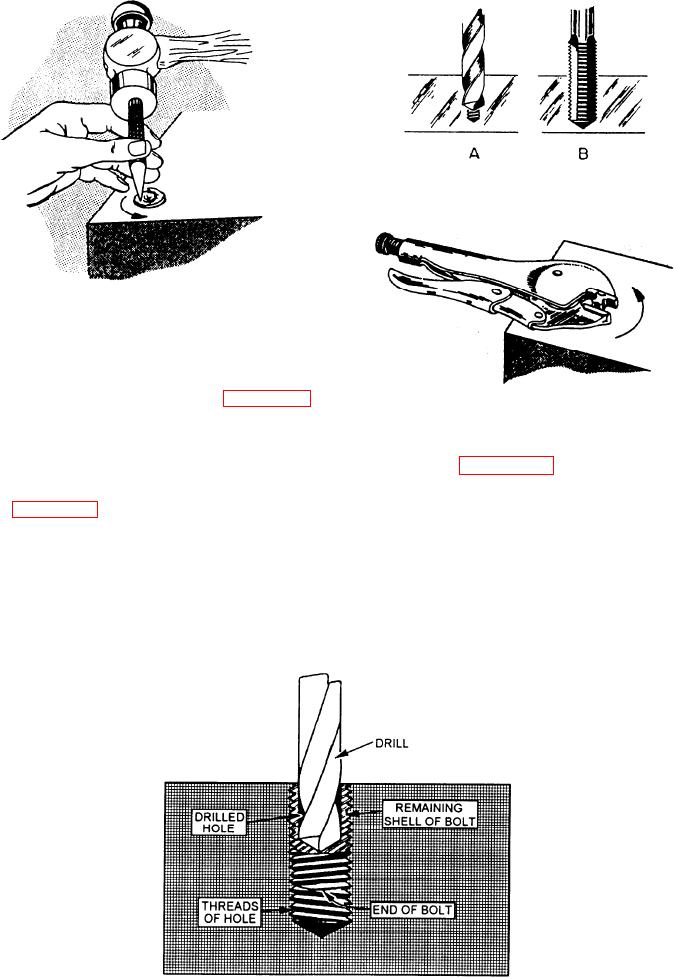

Figure 13-19.--Removing a broken bolt and retapping the hole

to a larger size.

Figure 13-17.--Removing a broken bolt with a prick punch.

If a bolt has been broken off flush with the surface,

you may sometimes back it out with light blows on a

prick punch or center punch, as shown in figure 13-17.

Figure 13-20.--Removing a broken tap with locking pliers.

To drill out a broken bolt and retap the hole, file the

bolt smooth, if necessary, and centerpunch it. Then

The drill in figure 13-18 has almost drilled the

select a twist drill that is a little smaller than the tap-drill

remaining part of the bolt away and will eventually

size for the particular bolt that has been broken. As

break through the bottom of the bolt. When this

shown in figure 13-18, this drill will just about but not

happens, all that will remain of the bolt will be a

quite touch the crests of the threads in the threaded hole

threaded shell. With a prick punch or other suitable tool,

or the roots of the threads on the threaded bolt. Carefully

chip out and remove the first two or three threads, if

start drilling at the center punch mark Crowd the drill

possible, at the top of the shell. Then carefully start a

one way or the other as necessary so that the hole will

tapered tap into these clean threads and continue

be drilled in the exact center of the bolt.

Figure 13-18.--Removing a broken bolt and retapping the hole to the same size.

13-16