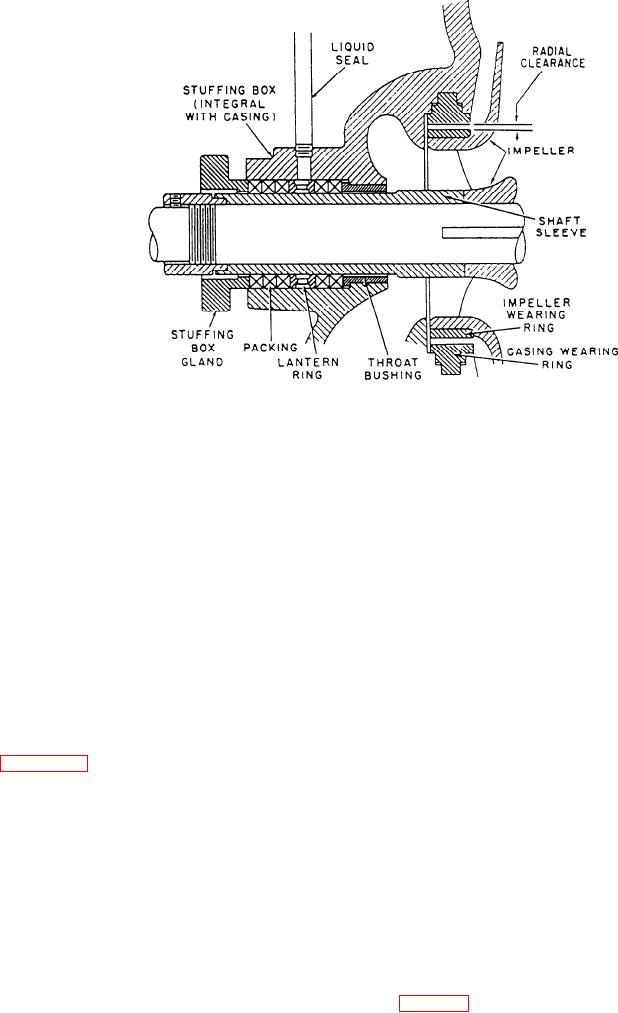

Figure 13-14.--Stuffhg box on a centrifugal pump.

In some pumps, the shaft sleeve is pressed onto the

casing wearing rings, impeller wearing rings, shaft, and

shaft sleeves in particular.

shaft with a hydraulic press, and you must machine off

the old sleeve in a lathe before you can install a new

The operation of a centrifugal pump wears away

one. On centrifugal pumps, the shaft sleeve is a snug

both the area of the shaft that goes through the packing

slip-on fit, butted up against a shoulder on the shaft and

gland or mechanical seal and the casing-impeller

held securely in place with a nut. The centrifugal pump

sealing areas. They must be renewed from time to time

sleeve-shaft-shoulder joint is usually made up with a

to maintain the efficiency of the pump.

hard fiber washer. It prevents liquid from leaking

through the joint and out of the pump between the sleeve

The shaft, casing, and impeller in a centrifugal

and shaft.

pump are designed so they can be renewed without

replacing them. The shafts have tightly fitted renewable

The impeller wearing ring is usually lightly press-

sleeves, while the casing and impeller have renewable

fitted to the hub of the impeller and keyed in with

surfaces called casing wearing rings and impeller

headless screws (also called Dutch keyed). To remove

wearing rings. You can see the arrangement clearly in

the worn ring, withdraw the headless screws or drill

them out and then machine the ring off in a lathe.

When it is necessary to renew these parts, the rotor

The amount of diametrical running clearance

assembly, consisting of the pump shaft, the impeller and

between the casing rings and the impeller rings affects

its wearing ring, and the casing rings, is usually brought

the efficiency of a centrifugal pump. Too much

into the shop. The following paragraphs explain the

clearance will let too much liquid leak back from the

method you should use to replace these parts.

discharge side to the suction side of the pump. Not

enough clearance will cause the pump to "freeze."

The repair parts generally are available from the

Before you install a new wearing ring on the impeller,

ship's allowance, but you may need to manufacture

measure the outside diameter of the impeller wearing

them. Before you proceed with these repairs, consult the

ring, and the inside diameter of the casing ring. (See

manufacturer's technical manual and the applicable

blueprints to get the correct information on vital

fig. 13-15.) If the measurements do not agree with the

clearances and other data.

lit and clearance data you have on hand, ask your

13-14