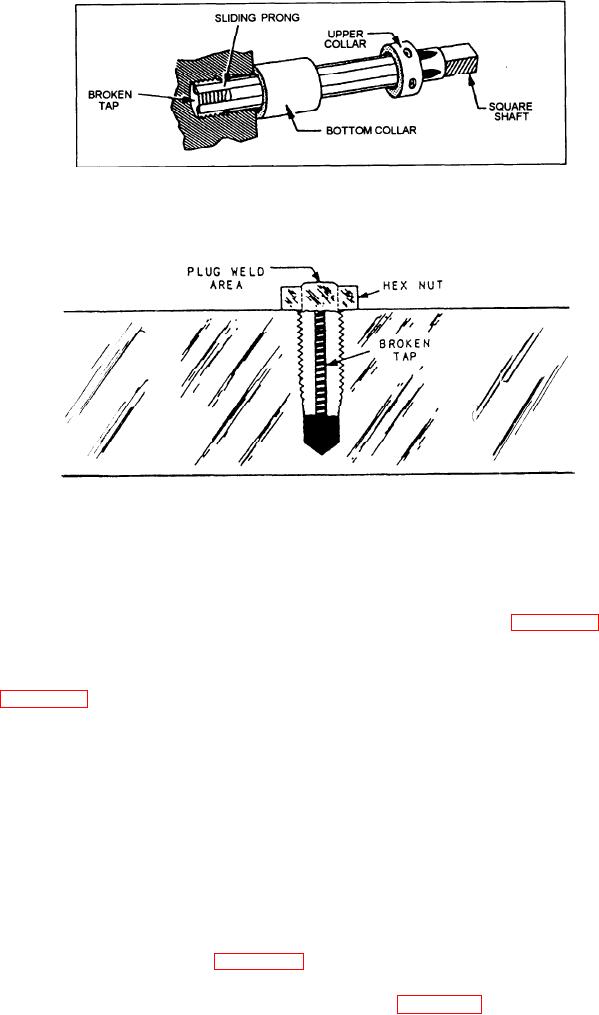

Figure 13-21.--Removing a broken tap with a tap extractor.

Figure 13-22.--Using a plug weld to remove a broken tap.

If the tap has broken off at or slightly below the

tapping until you have cut away the shell and restored

surface of the work, you may be able to remove it with

the original threads.

the tap extractor shown in figure 13-21. Again, apply a

In cases where it is not necessary to replace the

liberal amount of penetrating oil to the broken tap. Place

capscrew or bolt with one of the same size, use a drill

the tap extractor over the broken tap and lower the upper

larger than the broken bolt to drill out the old bolt, as

collar to insert the four sliding prongs down into the four

shown in figure 13-19, view A. Tap the hole first, and

flutes of the tap. Then slide the bottom collar down to

then finish it with a bottoming tap as shown in view B.

the surface of the work so it will hold the prongs tightly

against the body of the extractor. Tighten the tap wrench

Replace the original capscrew or stud with a larger size.

on the square shank of the extractor and carefully work

Never do this without the concurrence of your QA

the extractor back and forth to loosen the tap. You may

office.

need to remove the extractor and strike a few sharp

blows with a small hammer and pin punch to jar the tap

REMOVING A BROKEN

loose. Then reinsert the tap remover and carefully try to

TAP FROM A HOLE

back the tap out of the hole.

Each size of tap requires its own size of tap

To remove a broken tap that protrudes from a hole,

extractor. They come in the following sizes: 1/4, 5/16,

generously apply penetrating oil to the tap, working it

3/8, 7/16, 1/2, 9/16, 5/8, 3/4, 7/8 and 1 inch.

down through the four flutes into the hole. Then grasp

the tap across the flats with locking pliers. Figure 13-20

When a tap extractor will not remove a broken tap,

shows this operation. Carefully ease the tap out of the

you may be able to do it with the plug weld method

shown in figure 13-22. Place a hex nut over the tap and

hole, adding penetrating oil as necessary.

13-17