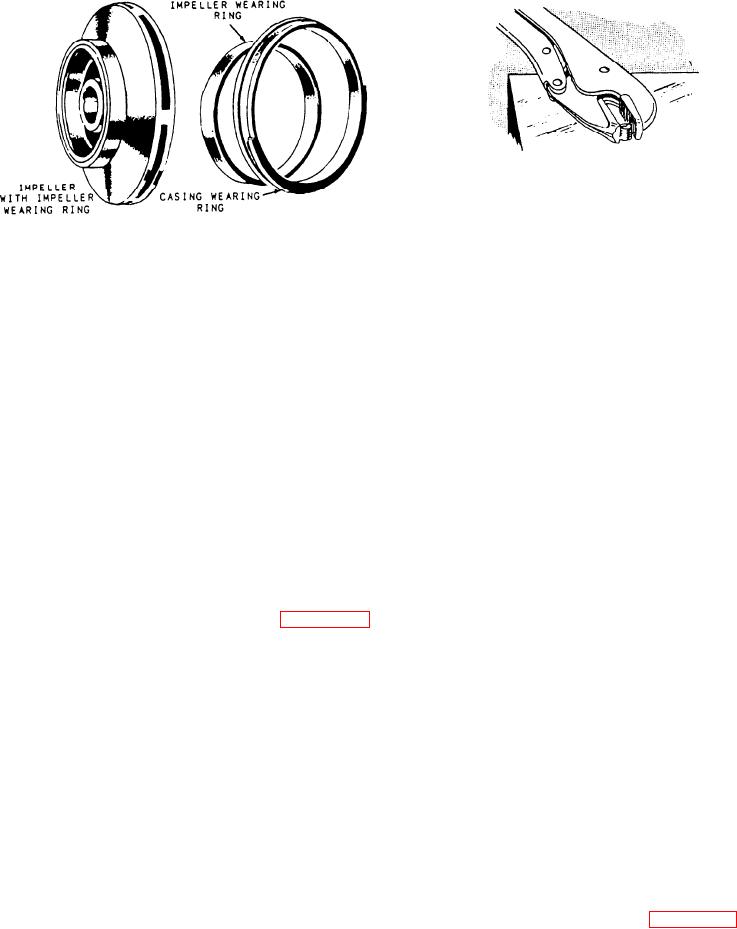

Figure 13-16.--Removing a broken stud with locking pliers.

Figure 13-15.--Impeller, impeller wearing ring, and casing

5. Remove the shaft assembly from the lathe.

wearing ring for a centrifugal pump.

6. Make the impeller rings. The size of the inside

diameter of the impeller rings should provide a

press fit on the impeller. The outside diameter

leading petty officer for instructions before you go any

should be slightly larger than the inside diameter

further. Sometimes it is necessary to take a light cut on

of the casing rings.

the inside diameter of the impeller ring to get its correct

press fit on the impeller hub. The difference between

7. Press the impeller rings on the impeller and lock

the outside diameter of the impeller wearing ring and

them in place with headless screws, if the

the inside diameter of the casing wearing ring is the

blueprint specifies it.

diametrical running clearance between the rings. If

this clearance is too small, correct it by taking a cut

8. Mount the shaft assembly back in the lathe and

on either the outside diameter of the impeller ring or

machine the diameter of the impeller rings to

the inside diameter of the casing ring. You also need

provide the proper clearance between impeller

to check the concentricity of the two rings. If they do

rings and casing rings. Blueprints and technical

not run true, machine their mating surfaces so they do

manuals list the clearance as either diametrical

run true. Be sure you keep the specified diametrical

or radial clearance. Diametrical clearance is the

clearance.

total amount of clearance required. Radial

clearance is one-half of the clearance required

When a pump like the one shown in figure 13-13

and must be doubled to get diametrical

needs repairs, usually only the shaft assembly and

clearance.

casing wearing rings are brought to the shop. To renew

the wearing rings and resurface the packing sleeves on

this type of pump, take the following steps:

REMOVING BROKEN BOLTS

AND STUDS

1. Clamp the casing wearing ring on a faceplate

and align the circumference of the ring

concentrically with the axis of the lathe spindle.

When you must remove a broken bolt or stud, flood

(You can hold the casing rings in a 4-jaw chuck,

the part being worked on with penetrating oil or oil of

but it may distort the ring.)

wintergreen. Soak the area for several hours or

overnight if you have time. A good soaking may loosen

2. Take a light cut on the inside diameter of the

a bolt that will otherwise have to be drilled out.

casing ring to clean up the surface. Do this to all

casing rings.

If enough of the broken piece protrudes, take hold

of it with locking pliers, as shown in figure 13-16, and

3. Mount the shaft assembly between centers or in

carefully try to ease it out. If you cannot turn the bolt,

a chuck and align its axis with the lathe axis.

soak it further with penetrating oil. If the oil doesn't

loosen the bolt, jar it with light hammer blows on the

4. Machine away the impeller wearing rings. Be

top and around the sides. This may loosen the threads

careful not to cut into the impeller.

so that you can remove the bolt with the pliers.

13-15