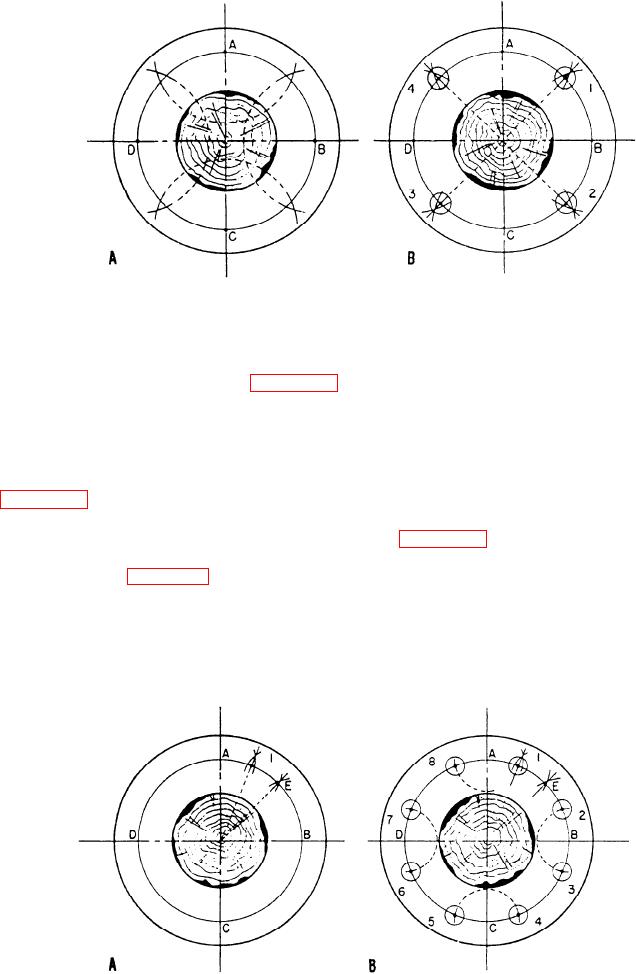

Figure 2-32.--Four-hole flange development.

prick-punch "witness marks" around the

accuracy, set your divider for the pitch between any

circumference, as shown in view B of figure 2-31.

two adjacent holes and step around the pitch circle. If

These witness marks will be cut exactly in half by the

the holes are not evenly spaced, find your error and

drill to verify a correctly located hole.

correct it. When the layout is correct, follow the

center-punching and witness-marking procedures

Four-Hole Flange

described for the 6-hole flange layout.

Figure 2-32 shows the development for a 4-hole

Eight-Hole Flange

flange layout. Set your dividers for slightly more than

half the distance of arc AB. Scribe an intersecting arc

Figure 2-33 shows the development of an 8-hole

across the pitch circle line from points A, B, C, and D,

flange. First locate point E by the same method

as shown in view A of figure 2-32. Next, draw a short

described to locate point 1 in the 4-hole layout. Then,

radial line through the point of intersection of each

divide arc AE in half by the same method. The

pair of arcs as shown in view B. The points where

midpoint of arc AE is the location for the center of the

these lines cross the pitch circle (1, 2, 3, and 4) are the

hole (1). (Set view A of fig. 3-33.) Next, set your

centers for the holes. To check the layout for

dividers for distance A (l), and draw an arc across the

Figure 2-33.--Eight-hole flange development.

2-16