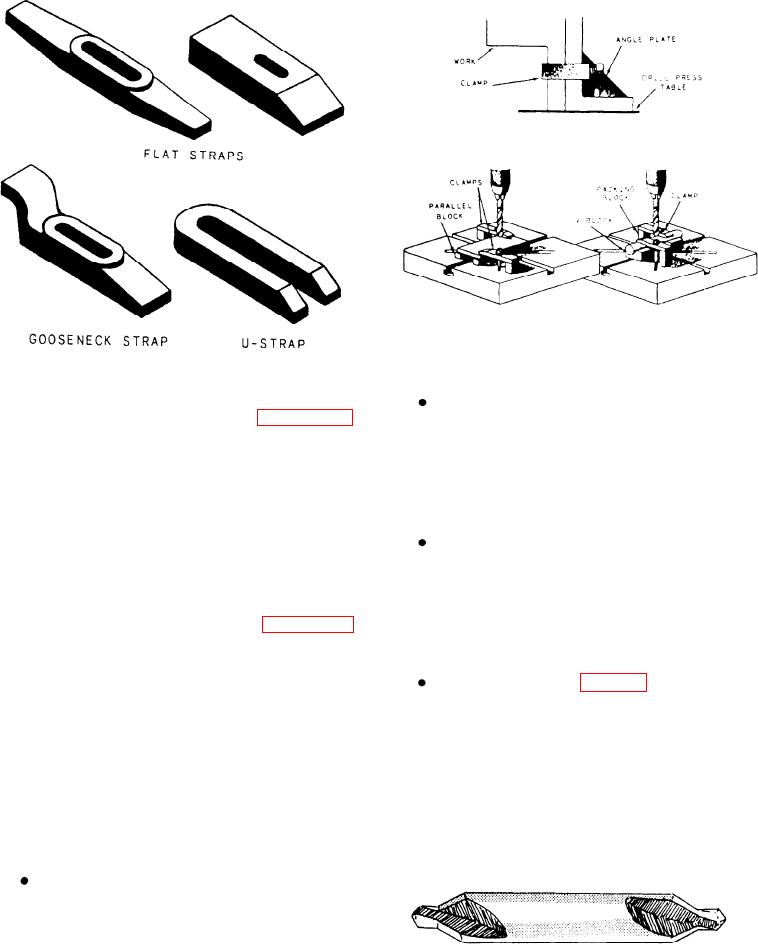

Figure 4-31.--Work mounted on the table.

Figure 4-30.--Common types of clamping straps.

Center punch the work at the point to be

types of clamping straps, shown in figure 4-30.

drilled. Position the center-punched workpiece

(Clamping straps are also identified as clamps or

under the drill. Use a dead center inserted in

dogs.) The U-strap is the most convenient for many

the spindle socket to align the center-punch

setups because it has a larger range of adjustment.

mark on the workpiece directly under the axis

of the spindle.

It is often necessary to use tools such as steel

parallels, V-blocks, and angle plates to support and

Bring the spindle with the inserted center down

hold the work. Use steel parallels to elevate the work

to the center-punch mark and hold it in place

above the table so you can better see the progress of

lightly while you fasten the locking clamps or

the drill. Use V-blocks to support round stock, and

dogs. This will prevent slight movement of the

angle plates to support work where you will drill a

workpiece, table, or both when they are

hole at an angle to another surface. Figure 4-31

clamped in position.

shows some examples of setups.

Insert a center drill (fig. 4-32) in the spindle

Drilling Hints

and make a center hole to aid in starting the

drill. This is not necessary on small drills on

which the dead center of the drill is smaller

To ensure accuracy in drilling, position the work

than the center-punch mark. But on large drills

accurately under the drill. Use the proper techniques

it will prevent the drill from "walking'* away

to prevent the drill from starting off center or from

from the center-punch mark. This operation is

moving out of alignment during the cut. Here are

especially important to drill holes on curved

some hints that will help you to correctly start and

surfaces.

complete a drilling job.

Before setting up the machine, wipe all foreign

matter from the spindle and the table. A chip in

the spindle socket will cause the drill to have a

wobbling effect which tends to make the hole

larger than the drill. Foreign matter on the

work holding device under the workpiece tilts

it in relation to the spindle, causing the hole to

Figure 4-32.--Combined drill and countersink (center drill).

be out of alignment.

4-20