through a part. However, you will need an angular

The taper pin reamer has a tapered body and is

used to smooth and true tapered holes and recesses.

drill to make a blind hole, one in which the angular

The taper pin reamer is tapered at 1/4 inch per foot.

hole does not go all the way through the part.

The expansion reamer is especially useful to

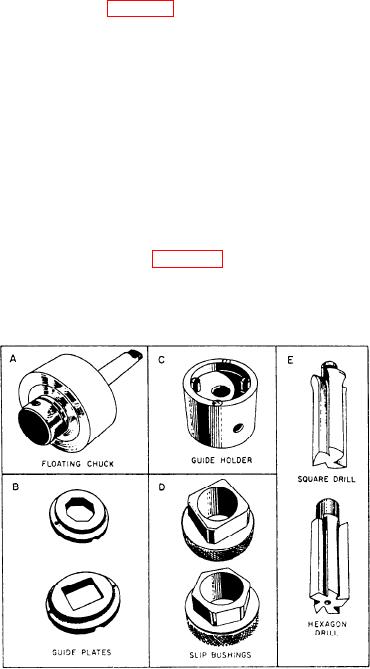

ANGULAR DRILL EQUIPMENT

enlarge reamed holes by a few thousandths of an inch.

It has a threaded plug in the lower end which expands

The equipment required to drill angular holes is

the reamer to various sizes.

specialized and is designed to do only this particular

operation. The following paragraphs contain a brief

To ream a hole, follow the steps outlined below:

description of the equipment. A complete description

1. Drill the hole about 1/64 inch less than the

of the equipment and its use is available from the

reamer size.

manufacturer when the equipment is ordered.

2. Substitute the reamer in the drill press without

Chuck

removing the work or changing the position of

the work.

The chuck (fig. 4-38A) used to drill angular holes

3. Adjust the machine for the proper spindle

is of an unusual design. While it holds the drill in a

speed. (Reamers should turn at about one-half

position parallel to the spindle of the lathe or drill

the speed of the twist drill.)

press and prevents it from revolving, it allows the drill

to float freely so that the flutes can follow the sides of

4. Use a cutting oil to ream. Use just enough

the angular hole in the guide plate. The chuck is

pressure to keep the reamer feeding into the

available with a Morse taper shank to fit most lathes

work; excessive feed may cause the reamer to

and drill presses. There are several different sizes of

dig in and break.

chucks, each capable of accepting drills for a given

5. The starting end of a reamer is slightly

range of hole sizes.

tapered; always run it all the way through the

hole. NEVER RUN A REAMER BACK-

Guide Plates

WARD because the edges are likely to break.

The guide plate (fig. 4-38B) is the device that

Tapping

causes the drill to make an angular hole. The

free-floating action of the chuck allows the drill to

Special attachments allow you to cut internal

screw threads with a tap driven by the drilling

machine spindle. They can save considerable time

when you must thread a number of identically sized

holes. The attachment is equipped with a reversing

device that automatically changes the direction of

rotation of the tap when either the tap strikes the

bottom of the hole or a slight upward pressure is

applied to the spindle down-feed lever. The reversing

action takes place rapidly, permitting accurate control

over the depth of the threads being cut. A

spiral-fluted tap should be used to tap a through hole

while a standard straight-fluted plug tap can be used

in a blind hole. A good cutting oil should always be

used in tapping with a machine.

DRILLING ANGULAR HOLES

An angular hole is a hole with a series of straight

sides of equal length. A square (4-sided), a hexagon

(6-sided), a pentagon (5-sided), and an octagon

Figure 4-38.--Equipment for drilling angular holes. A. Chuck;

B. Guide plate; C. Guide holder; D. Slip bushing; E.

8-sided) are examples of angular holes. You can use

Angular drill.

a broach to make an angular hole that goes all the way

4-23