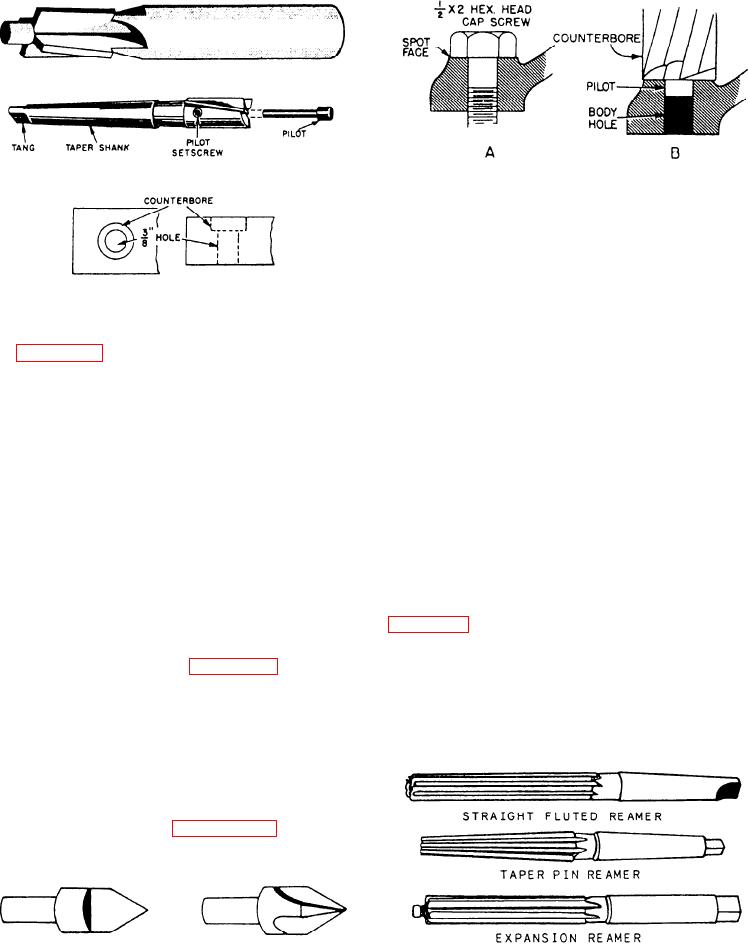

Figure 4-36.--Examples of spotfacing.

example of spotfacing and its use with fastening

devices. You will usually do this with a counterbore.

Reaming

Figure 4-34.--Two types of counterbore.

The drill press also may be used for reaming. For

Figure 4-34 shows two types of counterbores and

example, when specifications call for close

an example of a counterbored hole. The basic

tolerances, the hole must be drilled slightly undersize

difference between the counterbores illustrated is that

and then reamed to the exact dimension. Reaming

one has a removable pilot and the other does not. You

also removes burrs in a drilled hole or enlarges a

can use a conterbore with a removable pilot to

previously used hole for new applications.

counterbore a range of hole sizes by simply using the

appropriate size pilot. A counterbore with a fixed

Machine reamers have tapered shanks that fit the

pilot may be used only with holes of the same

drilling machine spindle. Be sure not to confuse them

dimensions as the pilot.

with hand reamers, which have straight shanks. You

will ruin hand reamers if you use them in a machine.

Countersinks are used to seat flathead screws

There are many types of reamers, but the ones

flush with the surface. The basic difference between

used most extensively are the straight-fluted, the taper

countersinking and counterboring is that a

pin, and the expansion types. They are illustrated in

countersink makes an angular sided recess, while the

counterbore forms straight sides. The angular point

of the countersink acts as a guide to center the tool in

The straight-fluted reamer is made to remove

the hole being countersunk. Figure 4-35 shows two

small portions of metal and to cut along the edges to

common types of countersinks.

bring a hole to close tolerance. Each tooth has a rake

angle that is comparable to that on a lathe tool.

Spotfacing is an operation that cleans up the

surface around a hole so that a fastening device can be

seated flat on the surface. This operation is

commonly required on rough surfaces that have not

been machined and on the circumference of concave

or convex workpieces. Figure 4-36 shows an

Figure 4-35.--Countersinks.

Figure 4-37.--Reamers.

4-22