If you use a drill smaller than the required size

to make a pilot hole, it will increase accuracy

by eliminating the need to do any cutting with

the dead center of the finishing drill. This will

decrease the pressure required to feed the

finishing drill, and decrease the width of cut

taken by each drill. In drilling holes over 1

inch in diameter, you may need to use more

than one size of pilot drill to increase the size

of the hole by steps until you reach the finished

size.

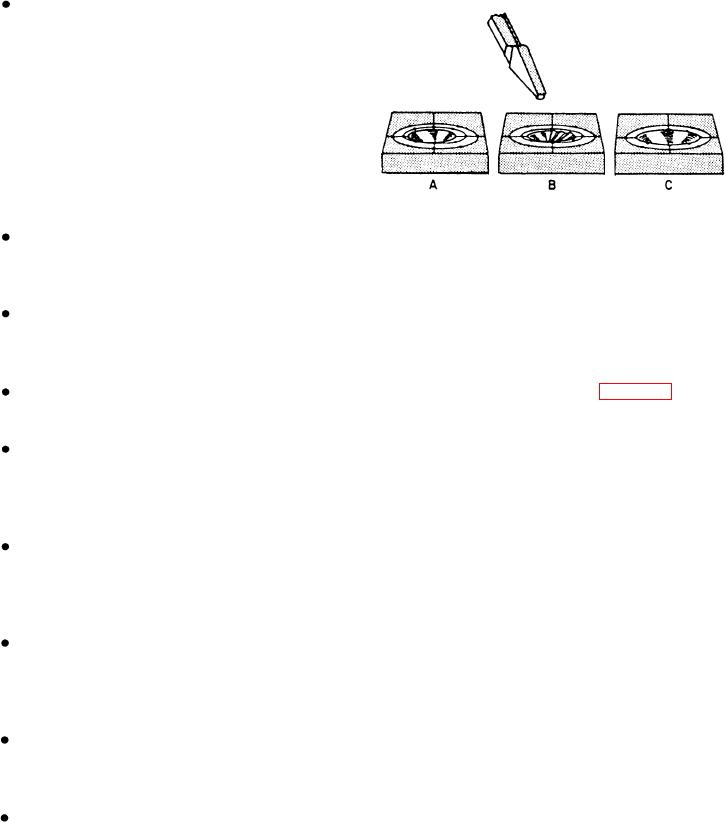

Figure 4-33.--Using a half-round chisel to guide a drill to the

correct center.

If the outer corners of the drill (margin) appear

to be wearing too fast or have a burnt look, the

drill is going too fast.

Correcting Offcenter Starts

If the cutting edges (lips) chip during drilling,

A drill may start off center because of improper

you have ground too much lip clearance into

center drilling, careless starting of the drill, improper

the drill, or you are using too heavy a feed rate.

grinding of the drill point, or hard spots in the metal.

To correct this condition, (See fig. 4-33.) take a

A very small drill will break easily if the drill is

half-round chisel and cut a groove on the side of the

not going fast enough.

hole toward which the center is to be drawn. The

depth of this groove depends upon the eccentricity

When you drill a hole that is more than three or

(deviation from center) of the partially drilled hole

four times the drill diameter in depth, back out

with the hole to be drilled. When you have drilled out

the drill frequently to clear the chips from the

the groove, lift the drill from the work and check the

flutes.

hole for concentricity with the layout line. Repeat the

If the drill becomes hot quickly, is difficult to

operation until the edge of the hole and the layout line

feed, squeals when being fed and produces a

are concentric.

rough finish in the hole, it has become dull and

requires resharpening.

When you use this method to correct an off center

condition, be very careful that the cutting edge or lip

of the drill does not grab in the chisel groove.

If the drill has cutting edges of different angles

Generally, you should use very light feeds until you

or unequal length, the drill will cut with only

one lip and will wobble in operation. This will

establish the new center point. (Heavy feeds cause a

produce an oversized hole.

sudden bite in the groove which may push the work

out of the holding device, or break the drill.)

If the drill will not penetrate the work, you

have ground insufficient or no lip clearance

Counterboring, Countersinking, and

into the drill.

Spotfacing

The majority of drilled holes will be oversized

regardless of the care you take to ensure a good

A counterbore is a drilling tool used in the drill

setup. Generally, you can expect the oversize

press to enlarge portions of previously drilled holes.

to average an amount equal to 0.004 inch times

The purpose is to allow the heads of fastening devices

the drill diameter plus 0.003 inch. For

to be flush with or below the surface of the workpiece.

example, you can expect a 1/2-inch drill to

The parts of a counterbore that distinguish it from a

produce a hole approximately 0.505 in

regular drill are a pilot, which aligns the tool in the

diameter ([0.004 X 0.500] + 0.003). This

hole to be counterbored, and the cutting edge of the

amount can vary up or down depending on the

counterbore, which is flat so that a flat surface is left

condition of the drilling machine and the twist

at the bottom of the cut, enabling fastening devices to

drill.

seat flat against the bottom of the counterbored hole.

4-21