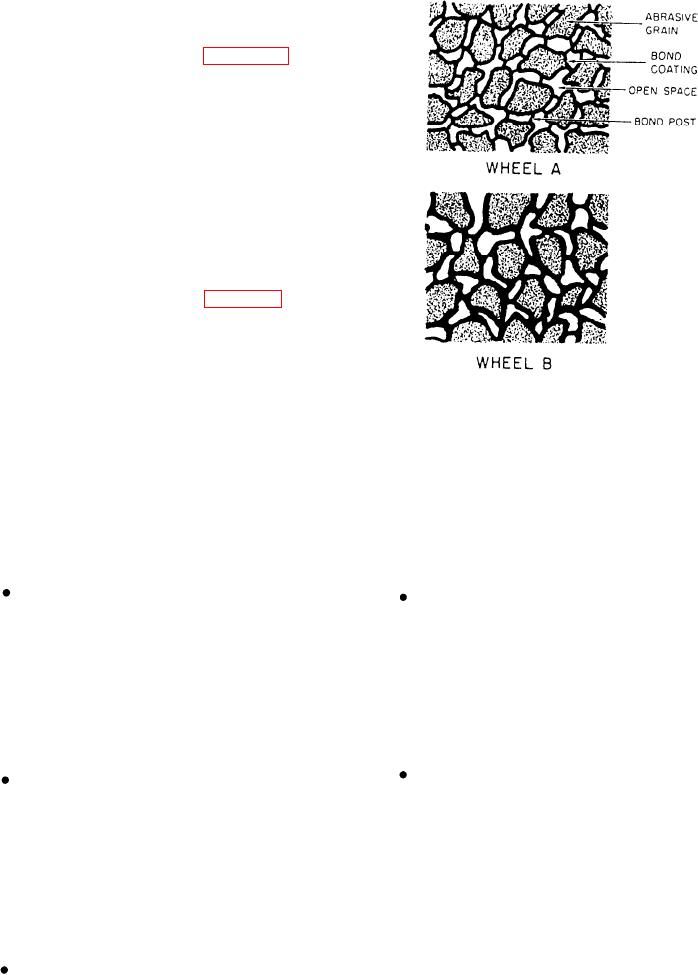

the abrasive is soft or hard; it means that the wheel has

either a small amount of bond (soft grade) or a large

amount of bond (hard grade). Figure 5-5 shows

magnified portions of both soft-grade and hard-grade

wheels. You can see that a part of the bond surrounds

the abrasive grains, and the remainder of the bond

forms into posts that hold the grains to the wheel and

hold them apart from each other. The wheel with the

larger amount of bonding material (hard grade) has

thick bond posts and offers great resistance to

grinding pressures. The wheel with the least amount

of bond (soft grade) offers less resistance.

4. Structure: The structure is designated by

numbers from 1 to 15. It refers to the open space

between the grains, as shown in figure 5-5. Wheels

with grains that are very closely spaced are said to be

dense; when grains are wider apart, the wheels are

said to be open. Open-grain wheels will remove more

metal faster than close-grain wheels. Also, dense, or

Figure 5-5.--How bond affects the grade of the wheel. Wheel

close grain, wheels normally produce a finer finish.

A, softer; wheel B, harder.

Structure makes up about 20 percent of the grinding

wheel.

5. Bond type: The bond makes up the remaining

stamped out of this sheet and heated in a pressurized

40 percent of the grinding wheel and is one of its most

mold until the vulcanizing action is complete. These

important parts. The bond determines the strength of

wheels are very strong and elastic, and they are used

the wheel. The five basic types of bond are vitrified,

as thin cutoff wheels. They produce a high finish and

silicate, rubber, resinoid, and shellac. We will

you can run them at speeds between 9,500 and 16,000

describe each of them in the following paragraphs:

sfpm.

Vitrified bond is designated by the letter V.

Resinoid bond wheels are designated by the

About 75 percent of all grinding wheels are made with

letter B. Resinoid bond is made from powdered or

vitrified bond. It is not affected by oil, acid, or water.

liquid resin with a plasticizer added. The wheels are

Vitrified bond wheels are strong and porous, and rapid

pressed and molded to size and fired at approximately

temperature changes have little effect on them.

320F. The wheels are shock resistant and very

Vitrified bond is composed of special clays. When

strong and they are used for rough grinding and as

heated to approximately 2300F, the clays form a

cutoff wheels. Like rubber bond wheels, you can run

glasslike cement. Do NOT run vitrified bond wheels

these wheels at a speed of 9,500 to 16,000 sfpm.

faster than 6,500 surface feet per minute (sfpm).

Shellac bond wheels are designated by the

Silicate bond is designated by the letter S. This

letter E. They are made from a secretion from Lac

bond is made of silicate of soda. Silicate bond wheels

bugs. The abrasive and bond are mixed, molded to

are used mainly on large, slow rpm machines where a

shape, and baked at approximately 300F. Shellac

cooler cutting action is wanted. Silicate bond wheels

bond wheels give a high finish and have a cool cutting

are softer than vitrified wheels, and they release the

action when used as cutoff wheels. You also can run

grains more readily. Silicate bond wheels are heated

these wheels at speeds between 9,500 and 12,500

to approximately 500F when they are made. Like

sfpm.

the vitrified bond wheel, do not run this one at a speed

greater than 6,500 sfpm.

6. Manufacturer's Record Symbol: The sixth

Rubber bond wheels are designated by the

station of the grinding wheel marking is the manu-

letter R. The bond consists of rubber with sulphur

facturer's record. This may be a letter or number, or

added as a vulcanizing agent. The bond is made into

both. The manufacturer uses it to designate bond

a sheet into which the grains are rolled. The wheel is

modifications or wheel characteristics.

5-4