1/4 inch thick. An SD150R100B grinding wheel is

normally recommended.

Chip breaker grinders have a coolant system that

either floods or slowly drips coolant onto the tool

being ground. The main objective is to prevent the

grinding wheel from loading up or glazing over from

the grinding operation.

CUTTING TOOL MATERIALS

The materials used to make machine cutting tools

must be hard enough to cut other metals, be wear

resistant, have impact strength to resist fracture, and

keep their hardness and cutting edge at high

temperatures. Several different materials are used for

cutting tools, and each one has properties different

from the others. Selection of a cutting tool material

depends upon the metal to be cut and the conditions

under which it will be cut.

HIGH-SPEED STEEL

High-speed steel is a widely used cutting tool

material. High-speed steel tools can maintain their

hardness and abrasion resistance under the high

temperatures and pressures generated during the

general cutting process. Although the hardness of a

high-speed tool (Rc 60-70) is not much greater than

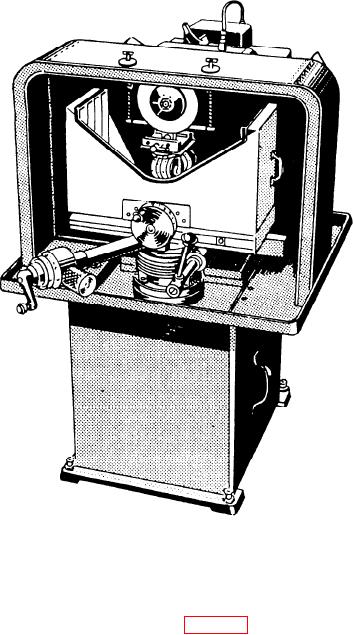

Figure 5-11.--Chip breaker grinder.

that of carbon-steel tools, high-speed steel begins to

lose its hardness at a tempering temperature of 1,000

to 1,100F. Machine shops generally use two types of

CHIPBREAKER GRINDER

high-speed tools: tungsten high-speed steel and

A chip breaker grinder (fig. 5-11) is a specialized

molybdenum high-speed steel. These designations

grinding machine. It grinds grooves or indentations

show the major alloying element in each of the two

on the top surface of carbide tools to control the

types. Both types resist abrasive wear, remain hard at

direction and length of the chips produced in cutting

high temperatures, and keep a similar degree of

metal. Later in this chapter, we'll describe the types

hardness. The molybdenum high-speed steel is

of chip breakers that are commonly ground on carbide

tougher than the tungsten and is more effective in

tools.

machinery operations where interrupted cuts are

made. In an interrupted cut, such as cutting

The chip breaker grinder has a vise you can adjust

out-of-round or slotted material, the cutter contacts

to four different angles to hold the tool to be ground.

the material many times in a short period of time.

These angles are the side cutting edge, back rake, side

This "hammering" effect dulls or breaks cutters that

rake, and chip breaker, and we'll explain them later in

are not tough enough to withstand the shock effect.

this chapter. The vise is mounted so you can move it

back and forth under the grinding wheel. Both the

CAST ALLOYS

cross feed used to position the tool under the grinding

wheel and the vertical feed used to control the depth

Cast alloy tool steel usually contains varying

of the chip breaker are graduated in increments of

amounts of cobalt, chrome, tungsten, and molybdenum.

0.001 inch.

Tools made from these steels are generally more

The chip breaker grinder uses a diamond wheel.

efficient than tools made from high-speed steel,

retaining their hardness up to an operating tempera-

It is usually a type 1 straight wheel but differs from

ture of approximately l,400F. This characteristic

other type 1 wheels because it is normally less than

5-8