circumference and back of the grinding wheels as a

WHEEL CARE AND STORAGE

safety device, and an adjustable toolrest mounted in

front of each wheel to support the tool bits while they

It's easy to damage or break grinding wheels if

are being ground.

you mishandle them or store them improperly.

Whenever you handle them, take care not to drop

While you grind on the periphery of the wheel on

them or bump them against other hard objects.

a pedestal grinder, you will grind on the side of the

Store grinding wheels in a cabinet or on shelves

wheel on a carbide tool bit grinder. The straight cup

large enough to allow selection of a wheel without

wheel (fig. 5-10) is similar to the wheels used on most

disturbing the other wheels. The storage space should

carbide tool bit grinders. Some carbide tool grinders

protect against high humidity, contact with liquids,

have a straight cup wheel on one side of the grinder

freezing temperatures, and extreme temperature

and a straight wheel, such as the type used on a

changes. Also secure grinding wheels aboard ship to

pedestal or bench grinder, on the other side.

prevent them from being damaged when the ship is at

sea. Stack thin cutoff wheels on a rigid surface

The adjustable toolrest has an accurately ground

without any separators or blotters between them.

groove or keyway across the top of its table. This

Stack flaring cup wheels flat with the small ends

groove holds a protractor attachment that you can set

together. Store all other types of wheels upright on

to the desired cutting edge angle. The toolrest will

their rims with blotters between them. A sheet metal

also adjust to permit grinding the relief angle.

cabinet lined with felt or corrugated cardboard to

prevent wheel chipping makes good storage.

If your carbide tool grinder has a coolant system,

be sure you direct an ample, steady stream of coolant

CARBIDE TOOL GRINDER

at the point where the tool meets the wheel. An

irregular flow may allow the tool to heat up and then

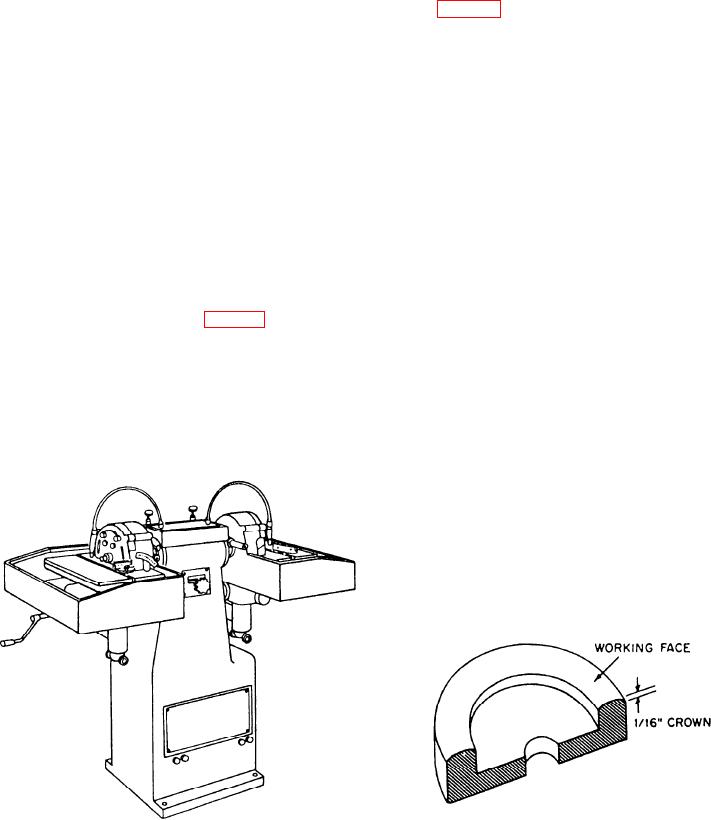

The carbide tool grinder (fig. 5-9) looks much

be quenched quickly. which may crack the carbide. If

like a pedestal grinder with the toolrest on the side

your grinder has no coolant system, let the carbide

instead of the front. The main components of the

cool in the air; do NOT dip it in water when it

carbide tool grinder are a motor with the shaft

becomes hot.

extended at each end to mount the grinding wheels,

the pedestal that supports the motor and is fastened to

the deck, wheel guards mounted around the

Carbide-tipped tool bits may have either disposable

or brazed cutting edges. The disposable-tip tool bit

needs no sharpening; just dispose of the tips when

their cutting edges become dull. Sharpen the

brazed-tip tool bit on the carbide tool bit grinder.

For best results with carbide-tipped tool bits, use

a silicon-carbide wheel for roughing and a diamond

impregnated wheel for finishing.

Figure 5-10.--Crown on the working face of a wheel for a

Figure 5-9.--Carbide tool grinder.

carbide tool bit grinder.

5-7