28.116

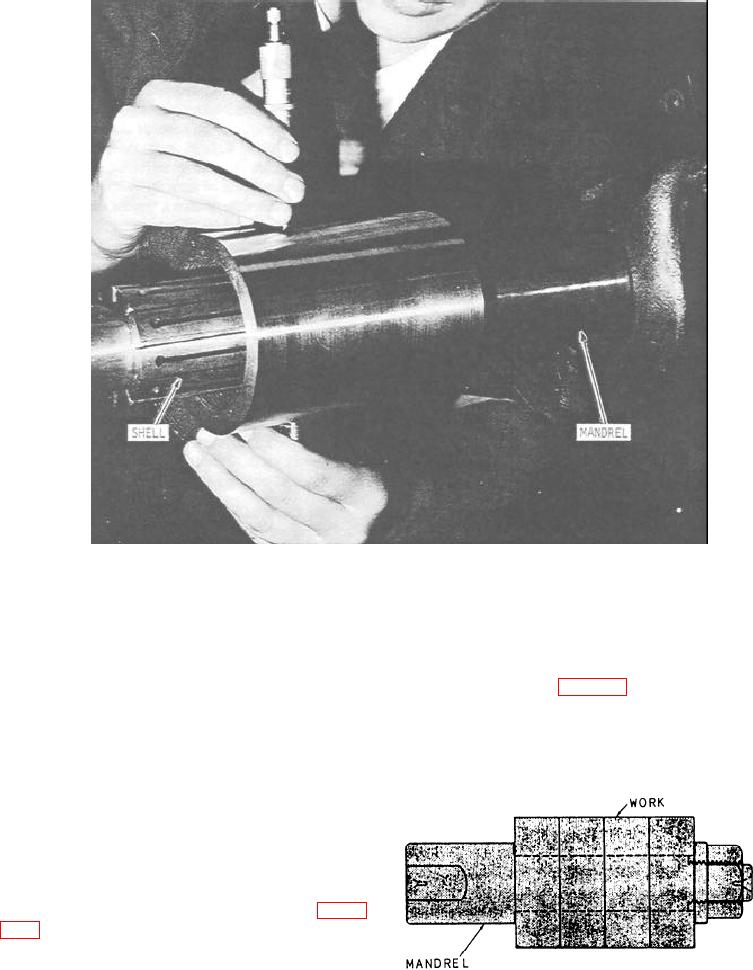

Figure 6-48.--A split-shell expansion mandrel.

ends of the mandrel when you press or drive it into the

the shell, causing it to expand until it holds the work

work. A piece of work mounted on a mandrel must

properly.

have a tighter press fit to the mandrel for roughing

A GANG mandrel (fig. 6-49) is used for holding

cuts than for finishing cuts. Thick-walled work can

several duplicate pieces such as gear blanks. The

be left on the mandrel for the finishing cut, but

pieces are held tightly against a shoulder by a nut at

thin-walled work should be removed from the

the tailstock end.

mandrel after the roughing cut and lightly reloaded on

the mandrel before the finish cut is taken.

In addition to the standard lathe mandrel just

described, there are expansion mandrels, gang

mandrels, and eccentric mandrels.

An EXPANSION mandrel is used to hold work

that is reamed or bored to nonstandard size. Figure

6-48 shows an expansion mandrel composed of two

parts: a tapered pin that has a taper of approximately

1/16 inch for each inch of length and an outer split

shell that is tapered to fit the pin. The split shell is

Figure 6-49.--Gang mandrel.

placed in the work and the tapered pin is forced into

6-28