TM 55-2815-574-24

0043

INSPECT - Continued

NOTE

The diameter at position C and D is the average of the four cylinder bore gauge readings.

Position C measurement shall not exceed 5.2180 in. (132.5372 mm). d.

c.

Position D measurement shall not exceed 5.2180 in. (132.5372 mm).

3.

Should any cylinder bore (51) exceed limits, replace engine block (4).

4.

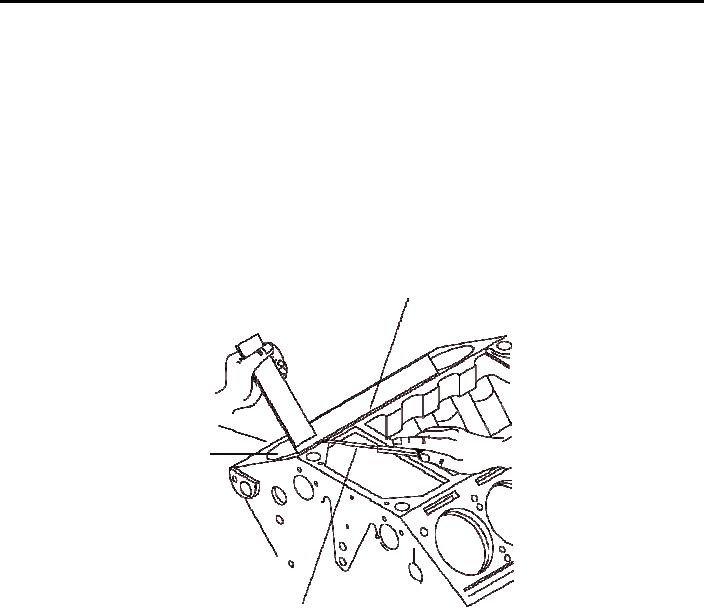

Using a straight edge and feeler gage, measure engine block (4) flatness crosswise between all cylinder

bores (51).

STRAIGHT

EDGE

4

51

FEELER

GAGE

5.

Should engine block flatness vary more than 0.003 in. (0.076 mm), replace engine block (4).

6.

Using a straight edge and feeler gage, measure engine block (4) flatness lengthwise between all cylinder

bores (51).

7.

Should engine block (4) flatness vary more than 0.007 in. (0.178 mm), replace engine block.

NOTE

Cylinders may be counterbored to either of two depths.

8.

Using a counterbore depth gauge, measure cylinder bore (51) counterbore depth at point A.

0043-11