TM 55-2815-574-24

0043

INSPECT ENGINE BLOCK - Continued

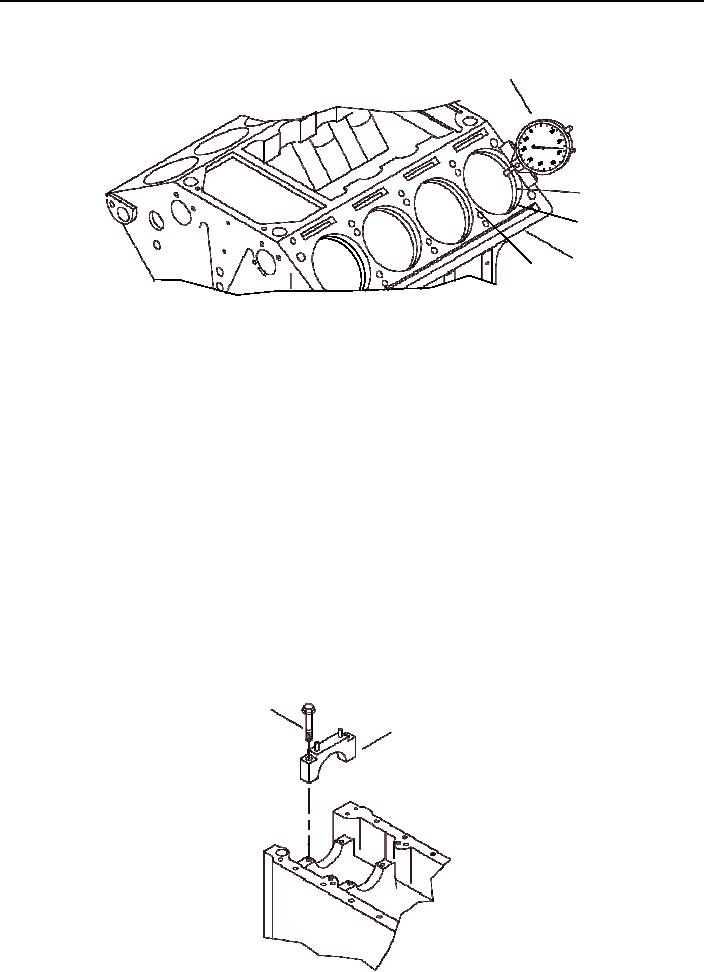

COUNTERBORE

DEPTH GAGE

A

51

4

B

NOTE

Depths not meeting the following measurements may be corrected by changing the

cylinder liner thickness.

9.

Counterbore depth at point A shall be between 0.4755 and 0.477 in. (12.13 and 12.12 mm) or between

0.4905 and 0.4920 in. (12.46 and 12.50 mm). Should measurements be out of tolerance, replace engine block (4).

10. Should the counterbore at point A vary more than 0.0015 in. (0.04 mm) around the edges of the cylinder, replace

the engine block (4).

11. Should the difference between any two adjacent cylinder counterbores at point B be more than

0.0015 in. (0.04 mm), replace engine block (4).

NOTE

Main bearing caps must be installed in same position as marked during removal. Make sure

the caps are firmly seated and the bearings are removed.

12. Install five main bearing caps (54) and ten hex head screws (55)

55

54

0043-12